Grow lights are the cornerstone of any indoor or light-assisted greenhouse cultivation facility. After all, light is the driving force behind photosynthesis, which creates all the energy within a plant.

Grow lights are available in a variety of power requirements and color spectrums to help plants reach their maximum potential. Matching the light spectrum and intensity to your goals is crucial when designing a facility. Factors to be considered include the stage of growth planned for the space and whether plants will be grown under a single setup throughout their cycle. A clearly defined cultivation plan will impact lighting selection.

Lighting types

Traditionally, indoor cultivators have employed metal halide (MH) or high-pressure sodium (HPS) lights capable of producing a high amount of photosynthetic active radiation (PAR) over a large footprint. Many facilities have transitioned to using light-emitting diode (LED) lights thanks to advancements in diode technology that allow LED fixtures to match the amount of PAR produced by traditional bulbs.

HPS and MH bulbs produce unique spectrums of light that are best suited for different stages of plant growth. The bulb is connected to a ballast, which provides the proper operational wattage. Both HPS and MH setups must be monitored closely, because they produce significant heat.

LED lights consist of LED chips mounted onto a heat sink and wired to a driver. The driver controls how much power is delivered to the diodes and can be either mounted to the fixture or wired outside the grow room. Drivers dim the lights as well as adjust their spectrum. Many different grades of LED lights and drivers are available, so it’s essential to know what parts manufacturers use to build their fixtures and systems.

Sensors such as PAR meters are used to monitor how much photosynthetic light is available for the canopy, allowing growers to adjust the light intensity and spectrum. This can be helpful in spaces with lower ceilings, as light intensity should be decreased as plants grow taller and closer to the fixtures. Lights with dimming capabilities typically are controlled using a zero- to ten-volt electrical signal capable of adjusting the intensity and on-off schedule.

Choose the right light

The number of options can make choosing the best setup for a facility seem overwhelming. Begin the process by determining the goals for the space. Clones and seedlings require very little photosynthetic energy. As plants mature, they require more energy, and therefore light, to help them sustain growth and produce large, resinous colas.

Ensuring the light spectrum matches the stage of growth also is important. Plants in the vegetative stage perform best under lights that produce a heavy blue spectrum. When plants switch to flowering, they prefer a red spectrum.

Next, look at the footprint. The goal is to cover the canopy as evenly as possible. Lighting manufacturers typically supply a light map with their fixtures showing the wavelengths produced by the fixture and sometimes the dimensional footprint of the lights with the amount of light energy available at different heights. This information reveals how much vertical space is needed for even coverage.

Growing with their tops too close to a light source can damage plants’ cells and cause slow or abnormal growth. If vertical space is an issue and you cannot move the light source away from the plants, you’ll likely want to use controllers to dim the lights. Controllers adjust intensity or spectrum based on cultivator input. Some controllers integrate with specialized sensors to make changes automatically based on growth cycle or preprogrammed commands. Controllers allow growers to place lights closer to the plants and adjust the intensity to match growth stage.

Don’t forget to consult an electrician. Grow lights can consume more than three amps of electricity, and knowing what kind of power each electrical circuit can handle will help determine whether more power should be installed.

One final consideration is how lights may affect the environment. Lights produce heat, which must be removed from the grow room. Removing heat requires an exchange of air, which affects the humidity in the space and alters the vapor pressure deceit (used to determine how a plant is respiring and how water is moving from the roots into the growing environment). In addition to these parameters, carbon dioxide also should be monitored closely.

For plants to reach their full potential, they must have enough CO₂ available to aid in creating glucose—the building block in all new plant growth. Because the lights push the plant into photosynthetic overdrive, utilizing a CO₂ injection system will ensure plants have enough raw material to keep up with increased growth.

With so many types of lighting devices on the market, choosing the most appropriate system for your grow’s unique needs requires an investment of time and effort. It’s important to know what stages of plant growth will occur in the space, how much power is available, the amount of canopy, and what wavelength and intensity will best suit your goals. Once you can answer these questions, choosing a grow light will be easier.

Here are eight grow lights for cannabis to consider.

Grandmaster LED

- Programmable spectrum control, full-spectrum

- 120V to 240V

Grandmaster LED boasts an impressive lineup of light fixtures for growing spaces of any size. The brand offers numerous products to suit a variety of footprints, spectrums, and power outputs. Its newest fixture offers a programmable spectrum function that allows more than 900 custom wavelength settings.

Fluence

- Broad R3, R4, R6, and R8; dual R9B high-efficacy, dual R5B

- 120V to 480V

Fluence manufactures an array of LED lights for use in indoor spaces or greenhouses. The company offers lights with optimized spectrums and a controller capable of adjusting light output and scheduling. The catalog presents lights for every stage of growth, from propagation to flowering.

Horticulture Lighting Group

- Plant-centric white spectrum with deep red

- 120V to 240V

HLG offers made-in-the-USA lights for both home-growers and commercial cultivators. The company’s lineup includes lights with spectrums designed for optimized vegetative growth and flower production. HLG also offers light kits, allowing customers to purchase individual components and build their own LED fixtures.

TSRgrow

- White, vegetative, and “flower-power” spectrums

- 120V to 240V, HVDC

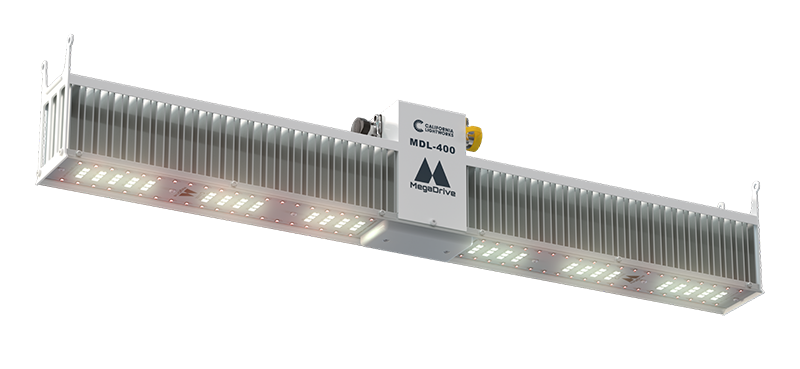

California Light Works

- Programmable spectrum control, full-spectrum

- 90V to 277V

Gavita

- Full-spectrum

- 120V to 480V

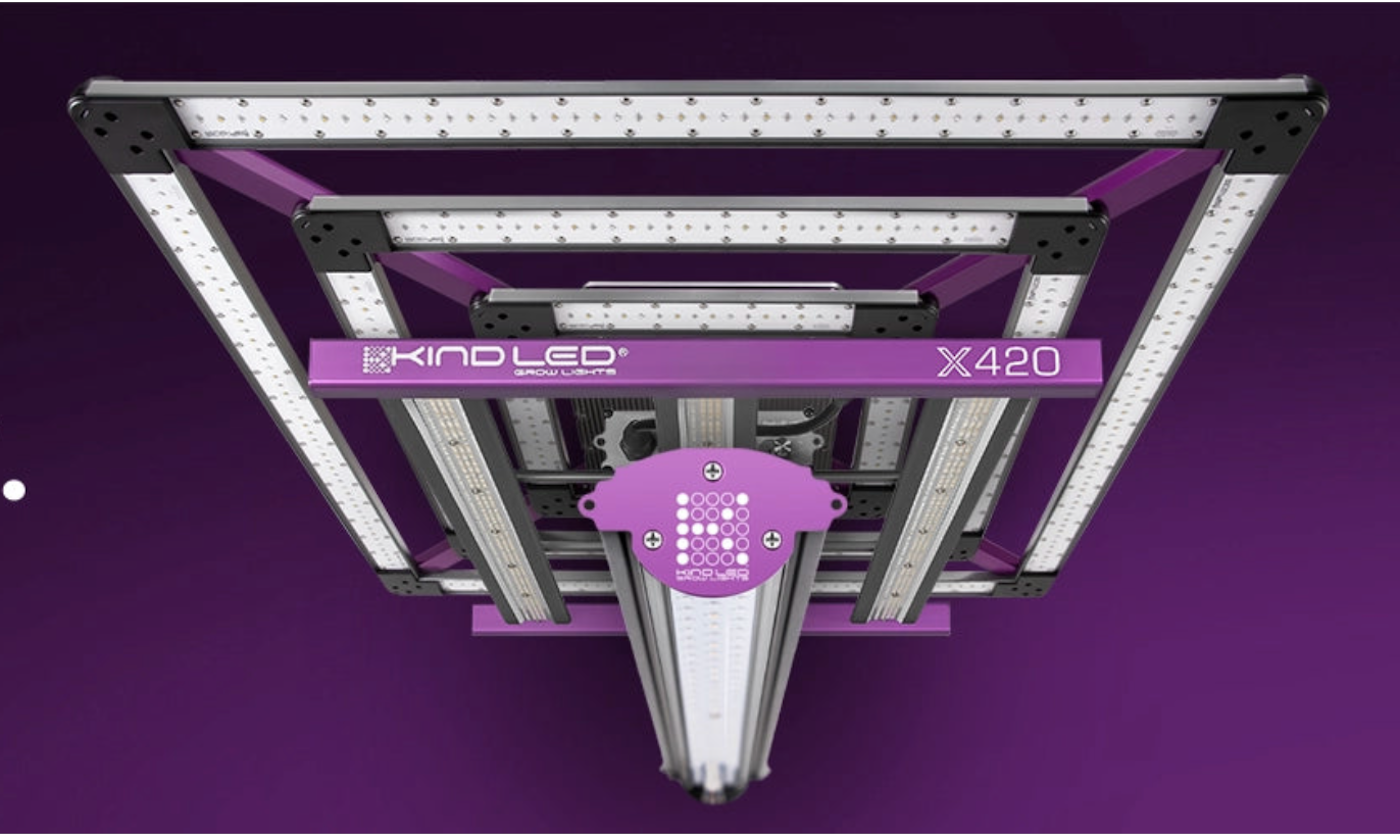

Kind LED

- Full-spectrum, tunable spectrum

- 120V to 277V

Philips

- Efficient white, broad white, efficient broad white

- 120V to 480V