With businesses fighting for every dollar, maximizing returns from the plant is a crucial component of success. The art of extracting cannabis flower into concentrates or hash can help companies create new products and utilize the plant to its full potential. Each extraction method presents its own set of challenges, but the right machines can mitigate these intricacies and help brands produce exceptional high-margin products.

The main types of cannabis extraction

Extraction consists of two different categories: solvent-based and solventless. Each method uses specialized machinery to separate the trichomes from the plant material, leaving behind high-quality concentrates with no residual solvents in the final product. Whether extracting THC, CBD oils, minor cannabinoids, or terpenes, there’s cannabis extraction equipment for any job and every type of extract.

Solvent-based method of extraction

Solvent extraction uses different hydrocarbons or alcohols to separate trichomes from plant material. Material is loaded into extraction tubes designed to handle extreme pressure and heat. The chosen solvent is passed through the plant material at a precise pressure and temperature before it’s purged to remove any residual solvents. What is left behind is pure, perfect hash.

The main solvents used in this method are ethanol, carbon dioxide (CO2), butane, and even propane. Alcohol extraction with ethanol is popular for tinctures and Rick Simpson Oil (RSO), while supercritical CO2 extraction is often used for large-scale essential oil and distillate production. Butane hash oil (BHO) became more prevalent in the cannabis market in the early 2010s thanks to the highly desirable resins it produces. The majority of solvent-based concentrates in dispensaries are created with butane THC extraction machines.

Solventless extraction

Solventless extraction uses water and different temperatures to create concentrates. First, plant material is mixed with water and ice in a mixing vat. The mixture is agitated and then strained through fine mesh screens. Each screen size contains a different grade of hash that can be refined.

After the hash has been sorted into different grades, it is either air-dried or freeze-dried before being pressed with high pressure and heat. After it’s pressed, the material is cured, resulting in a cannabis concentrate called rosin. While more time-consuming and often resulting in lower yields, solventless concentrates fetch a higher price point at dispensaries, leading to a net positive ROI.

Cannabis extraction equipment

With the concentrates market rapidly expanding, producers have many top-tier machines to consider. Here are some of the best cannabis extraction machines from the most popular manufacturers in 2024.

Beaker & Wrench 12” Wiped-Film Evaporation Turn-Key System

As one of the leading manufacturers of wiped film and solvent recovery solutions, Beaker & Wrench is trusted by THC extractors worldwide. Founded by a husband-and-wife lab chemist and engineer team, Beaker and Wrench designs equipment that efficiently and effectively produce pure distillates.

The 12” Wiped-Film Evaporation Turn-Key System arrives ready to operate, with an intuitive design simple enough for anyone to manage. An integrated 23-inch touch-screen panel provides seamless control, while a 200-liter feed tank, ACS 100 60 CFM dry-screw vacuum pump, and dual-stage cold trap allow for continual flow. The machine boasts production volumes of 15 to 30 liters per hour, maximizing efficiency and minimizing complications for profitable and worry-free operation.

Prodigy Processing Solutions ProX 80

A group of cannabis industry vets created Prodigy Processing Solutions to raise the operational efficiency bar. In addition to revolutionary extraction machines, the Ohio-based company provides post-processing solutions, lab consulting, and turnkey room build-outs to get new business units up and running as quickly as possible.

The Prodigy ProX 80 is the brand’s flagship device, offering high speed and precision. Featuring a 350-pound ASME-certified jacketed solvent and collection vessel and eight 10-pound jacketed material columns with in-line CRC, the device is capable of running 80 pounds of biomass an hour during passive operations and more than 100 pounds during active operations.

The ProX 80 can accommodate a wide range of solvents including butane, propane, isopropyl, and several mixed solvents. Since the machine runs at ultra-low temperatures, there’s no need for post-production winterization with products like distillate vapor pens and edibles.

Illuminated Extractors Behemoth R800

Illuminated Extractors offers efficient models for large and small-scale extraction. The company’s hydrocarbon extraction systems reduce input costs, alleviate excessive ancillary equipment, and produce high-quality extracts without added equipment.

The Behemoth R800 is the company’s top-of-the-line machine for commercial extraction, capable of running butane, ethanol, and propane solvents. It features ten material columns, two GD-1 wiped film evaporators, an IE 791 compressor, and solvent cycling, allowing for continuous processing capabilities. In addition to extraction machines, Illuminated Extractors also offers modular labs. These labs can be installed outdoors and stacked to create unique lab workflows.

BizzyBee Hexapod Modular Extraction System

BizzyBee Extractors boasts a diverse range of products engineered to swiftly and effectively extract cannabinoids and terpenes from cannabis biomass. Offering a wide range of modular solutions for both hydrocarbon and ethanol extraction, BizzyBee has an array of options for creating premium cannabis extracts at craft and high-volume scales.

In addition to performing passive solvent recovery, the Hexapod system offers low-temp, dewaxed extraction of cured and fresh frozen material. It features two material columns, two solvent columns, a collection vessel, a molecular sieve, and a solvent tank. Optional add-ons include a heat exchanger and filtration column to complete the unit. Depending on the final customizations, the BizzyBee can process anywhere from 40 to 100 pounds of material in eight hours.

Lowtemp Industries Osprey Washing Machine

Lowtemp Industries offers American-made processing equipment for home and commercial solventless extractors. The company manufactures a wide range of solutions for washing input materials for large and small-scale batches. The Osprey is Lowtemp’s top-shelf washing machine, capable of running up to 21,000 fresh frozen grams or 4,200 dry grams per two-hour wash cycle. The patent-pending square shape allows for maximum agitation by mixing from the bottom (up and over the top) instead of the counterclockwise motion many competitive machines use.

The Osprey includes automated mixing and custom recipes to ensure every strain gets the treatment it needs for maximum yields. The unit is available on its own or as part of a fully turnkey system that includes a nest recycling kit, water chiller, sieve collector, freeze dryer, and rosin press.

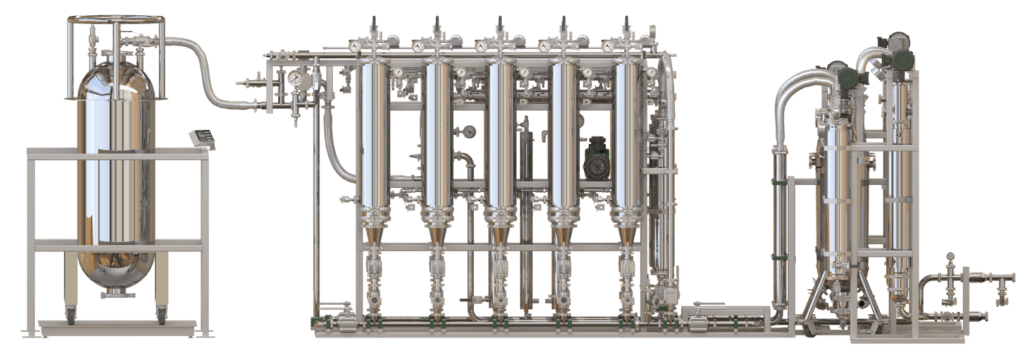

Evolved Genome Hydrocarbon Extraction System

Evolved Extraction Solutions is a Canadian company gaining ground in the American THC extraction market. The manufacturer offers closed-loop systems with hydrocarbon machines, ethanol extractors, and water hash equipment. Evolved also provides a large number of accessories and post-processing solutions, aiming to be a one-stop shop for commercial concentrate producers.

The Evolved Genome Hydrocarbon Extraction System utilizes a series of integrated closed-loop mechanisms the company refers to as “sequences.” The machine can run anywhere from 50 to 400 pounds of biomass per shift, depending on the type of finished material desired. The modular all-in-one system can provide in-line THCa crystallization, a potential game-changer for extractors who could generate 20kg of isolate in eight hours. Add-ons include Genome bottleneck-busting modules offering as much as a 100-percent increase in throughput.

HashTek 85t Commercial Bubble Hash Extraction System

Canadian company HashTek specializes in ice water extraction and dry sift. While Hashtek’s solutions are made in North America, they are still priced competitively with a lifetime warranty on craftmanship and lifetime support.

The HashTek 85t is the brand’s premier machine for commercial cannabis oil extractors with the ability for a single operator to produce five to ten pounds of rosin or melt per day. The unit features top-down agitation and sanitary stainless steel piping for recirculation, draining, fresh water, and rinse water. Hasktek’s patented tip-to-empty system sees the agitation tank mounted on a rotating axis for easy biomass removal. The company’s proprietary work screens also eliminate the need for 220u work bags. According to the manufacturer, a single 85t operator can produce more than $100,000 of product per day based on a wholesale price of $30 per gram.