Consumers love pre-rolls. The convenient product type is the second-most-popular behind flower, and it’s climbing fast. However, just one negative experience with a pre-roll can cause customers to back away from a brand forever.

A lot can go wrong with a seemingly simple joint, which is why quality control is everything. Fortunately, automated solutions can ensure not only that brands maintain rigorous stocking schedules but also that each pre-rolled joint meets the quality standards consumers demand. And the best part is automation can reduce staffing costs associated with traditional hand-rolled joints, resulting in higher profit margins and easier operations.

Calculating margins and return on investment related to machine rolling is the easy part. What’s not always so clear is how to choose the right automation partner, and that decision is equally important. Imagine investing hundreds of thousands of dollars in a pre-roll machine that delivers more headaches than revenue. Operators can’t afford to make the wrong choice.

“Quality is the first concern operators have when looking at a new machine,” said Shahar Yamay, cannabis division director for Hefestus Technologies. “The second concern is downtime, if it’s too complex, or if it’s going to leave them hanging after they paid so much for it.”

But what if quality were consistent and downtime minimized? What if the pre-roll machine was so smooth it practically ran itself? Imagine what that would do to your margins once the equipment was paid off. That’s the whole point of automation: employing a machine that takes the place of ten people or more, makes almost no mistakes, and doesn’t require extra pay to work overtime.

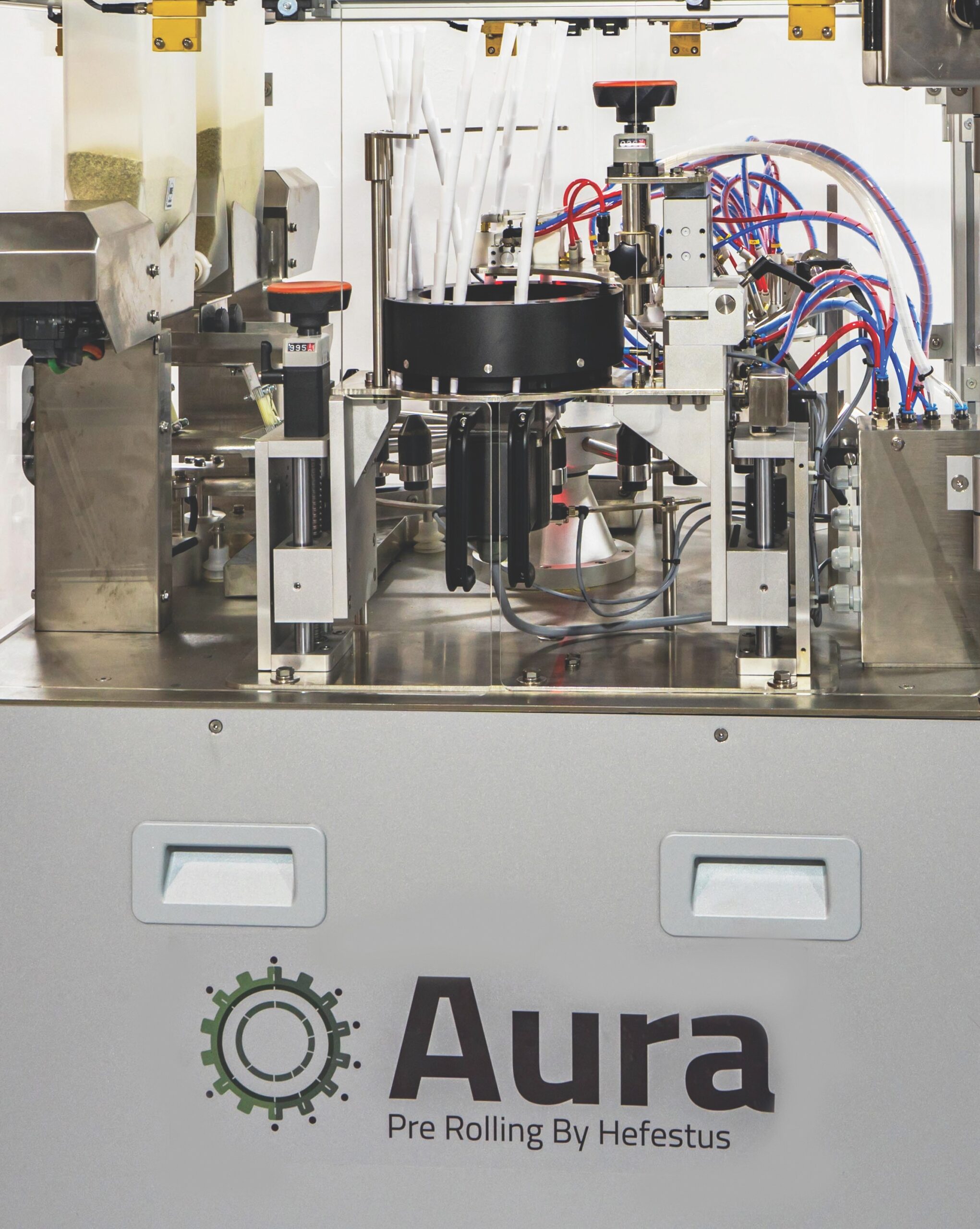

This was the vision behind Hefestus Technologies’ development of Aura-X, the newest addition to the company’s growing family of automated manufacturing machines.

“I love our machines. We don’t over-engineer, and we aim for simplistic sophistication,” Yamay said, adding Hefestus was founded in Israel in 1993 and in the years since has sold machines all over the world for multiple industries.

“We’re not just thinking like engineers,” he continued. “We’re actually trying to make a good joint. And we’re not doing anything tremendously new here. We collect information from the field and implement what we believe is best for our clients. This has been our approach with cannabis pre-roll automation for ten years now, starting in Israel.”

The Aura-X is surprisingly small for a machine that can manufacture thirty-six pre-rolls per minute. That’s enough output to replace up to sixteen manual laborers.

“Operators can also use the Aura-X to automate heavily infused pre-rolls, which is important because that’s where the industry is headed,” said Yamay. The Aura-X can process dense or light material, adjust for various cone sizes and paper lengths, and even cut the paper to a shorter size if desired. Joint customization options are almost limitless.

The Aura-X takes an innovative approach to filling cones. Instead of packing in the plant material, the machine holds the pre-rolls upright on a tamping vibration table while pouring the material, which mimics hand-tapping to create an evenly filled joint. Then, instead of twisting the end closed, the Aura-X utilizes hands-free tip-folding to achieve a perfect Dutch crown fold, which allows the pre-roll to burn evenly and makes lighting quicker and easier. The Aura-X also weighs the pre-rolls and puts them into tubes. A video on the company’s website shows the machine in action, demonstrating the smart, efficient design.

“My ideology about machines is they should be simple, easy to clean, easy to operate, and easy to maintain, and they should take up only a small amount of floor space,” said Yehuda Yamay, Shahar’s father and founder of Hefestus Technologies. He put thirty years of experience into designing the Aura-X. “Calibrating the machine, changing sets … everything should always be simple and very easy. You push the button, and that’s all.”

All machines break down at some point. The question is how much time they take to fix. “That’s the thing about our machines,” Shahar Yamay said. “They’re designed in a way that makes them easy to work with. We use common top-quality stock parts like Siemens and Festo, which means they’re easy to replace along with any needed virtual tech support through our U.S. office in Las Vegas.”

The Aura-X is designed to maximize uptime while manufacturing the best possible pre-rolls, ensuring operators get maximum return on investment. This is how operators scale while keeping their products on dispensary shelves.

“I love this industry,” Shahar Yamay said. “It’s like a house we’re all building together. When our processors are suffering, we’re suffering. When they’re growing, we’re growing. We really are in this together. It’s not like the food business, which has had the same machines for the past thirty years. The cannabis space is a fast-moving challenge, and we’ve positioned ourselves to add value and scale through automation.”

Hefestus will exhibit the Aura-X at MJBizCon 2023 in Las Vegas.

[…] with an automated pre-roll production system like Hefestus’s AuraX, which can produce up to 2,000 Dutch-crowned pre-rolls per hour while reducing staffing needs by as […]