If your company makes extracts, you have several options to choose from for vape hardware. But how do you choose? The cheapest? A recommendation from a colleague?

No matter how carefully crafted the extract, vaporizer hardware that doesn’t suit the concentrate can undermine the experience consumers expect. Get the hardware wrong, and customers will buy your product exactly once … and worse, probably complain to their friends about the poor quality.

Here are three critical aspects to consider when comparing options for vape hardware.

Hardware should suit the oil

Oil type matters when choosing hardware. Cannabis oil is known to interact with vape components such as the housing material. So, which type of oil are you formulating?

Distillates, CBD, and novel cannabinoids like delta-8 THC generally can be a good fit for polyresin tanks. Oils oxidize at a slightly faster rate in polyresin than they do in glass, so the material is best for fast-selling and relatively simple oils.

Not only does oxidation result in discoloration, but it also impacts terpenes and flavor—and more complex oils like live resin and rosins are likely to oxidize sooner in polyresin.

Polyresin usually is less expensive, enabling more competitive pricing for budget product lines. That’s especially important in the novel cannabinoid and CBD spaces because of their sizes and the amount of competition. In larger and more robust markets, pricing margins are critical.

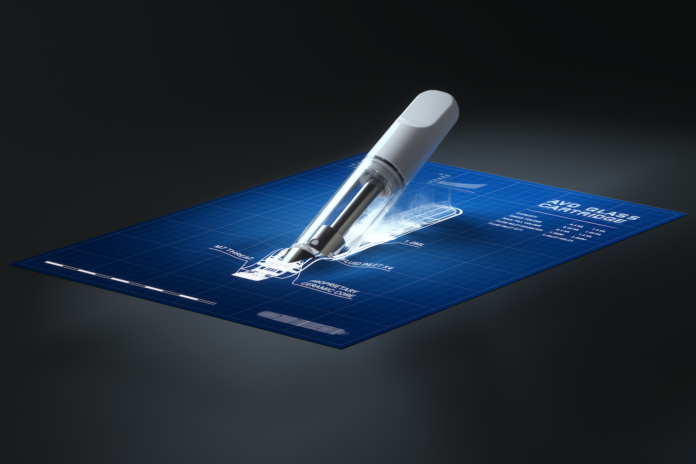

Terpene-rich oils like live resins, rosins, and other high-viscosity extracts benefit from borosilicate glass cartridges. They are non-porous and prevent external odors or other molecular residues from impacting the oil, thereby extending the product’s shelf life.

Borosilicate glass also can accommodate the widest variety of oil types. For example, if you have a budget distillate line and a higher-end live-resin line, rather than ordering two different types of cartridges, you can use glass for both. That translates to larger orders and access to more cost-effective pricing tiers in addition to streamlining production.

For premium oils like rosin and solventless, go with zirconia ceramic cartridges. Because they heat evenly, they help retain terpenes in complex oils and provide an optimal temperature distribution for smooth hits with unsurpassed flavor delivery.

Of equal need for consideration is the material used to manufacture the core of the cartridge.

Quartz cores are more turbulent for some oils and have a more rapid ramp rate. The ramp rate is the same as the heating time, and when it is quick, there are wider variances in detrimental temperature spikes than you’ll see in ceramic cores.

Quality ceramic cores heat evenly and consistently—an all-around better choice, no matter the oil type.

Avoid production headaches

Sure, cheap carts are everywhere, but will they meet the needs of your oil? You certainly can source off-the-shelf carts, but the quality may suffer and batches may not be consistent.

In terms of reliability, the tolerances that exist in manufacturing, design, and materials make all the difference—on the production line and in consumers’ hands. Tolerance refers to the dimensions and sizing that are specific to each component. Top-quality vape hardware has strict tolerances and allowances—parameters on the variability of each component—to maintain elevated reliability standards and expectations.

Use-case thresholds also fall under the reliability category. Consumers use their vapes in all types of scenarios and put the hardware through all manner of abuse. The higher the quality of the hardware, the less the chance consumers will be disappointed when a vape can’t handle unexpected or extreme conditions.

At the end of the day, a vape’s performance is what sets it apart. High-quality vape hardware should be crafted in a manner that ensures oil stability as well as consistent vaporization and flavor expression, which are what consumers notice most during the life cycle of the cartridge.

Vet vendors

The third consideration has nothing to do with cartridge component pros and cons. It’s about the hardware suppliers themselves.

Many vape companies are merely assemblers, but a vertically integrated supplier will have control over the entire raw-material supply chain. That means better quality control and consistency in product manufacturing. With all aspects of production handled in-house, a vertically integrated supplier can provide faster turnaround times for product development and delivery. Certifications, traceability, safety measures, and international standards ensuring vape hardware quality are the backbone of a vertically integrated supply ecosystem.

As we head toward federal legalization and the prospects of increased regulation and interstate commerce, transparency and accountability in vape manufacturing become even more important. If those are overlooked, the entire industry will suffer under the weight of less-than-optimal hardware.

Alexander Gordon is director of research and product development at Advanced Vapor Devices, a leading vertically integrated manufacturer and distributor of cannabis vaporizer technology. Previously, Gordon served as senior manager for closed systems and vapes at Greenlane Holdings Inc.

[…] brands to identify hardware to showcase their hard work on the farm and in the post-harvest room. Selecting the correct hardware partner for your concentrates is an arduous task in balancing cost, reliability, and consumer esteem when […]