As the cannabis industry tightens its belt, cultivators are under pressure to reduce costs without compromising output. Consequently, every decision must be strategic, efficient, and grounded in long-term sustainability. Increasingly, that means exploring automation — not as a luxury, but a necessity. The trend mirrors similar shifts in the food, pharmaceutical, and traditional agricultural sectors, where automation has become essential for safe, profitable scaling.

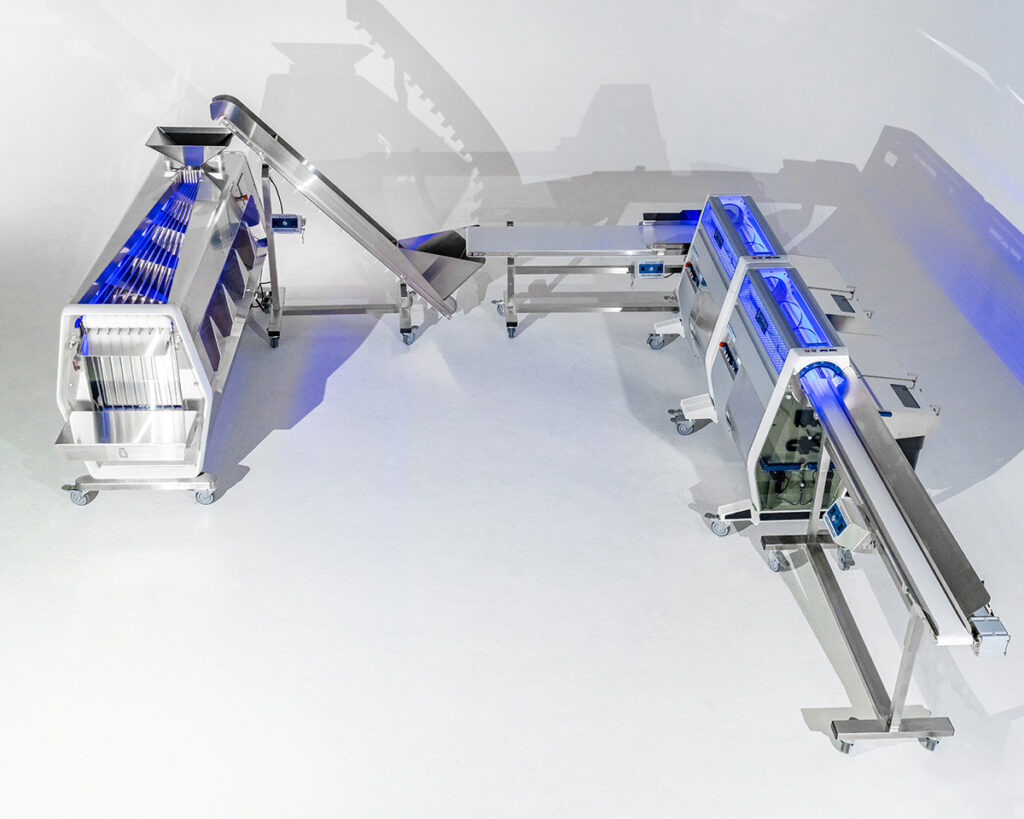

Mobius built its reputation in post-harvest processing technology by offering cultivators smart, scalable solutions to some of their toughest operational challenges. From reducing labor costs to accelerating return on investment (ROI) and maximizing yields, Mobius’s engineering-forward approach serves operators who are ready to treat their facilities like precision manufacturing hubs.

Preserving flower integrity with precision engineering

When cultivators consider automation, the most common concern is how machinery will affect the integrity of the flower. Mobius understands that worry and has data to address concerns.

“With the Mobius Automation Suite, maintaining the quality of the flower is not an issue,” said Mobius Account Executive Scott Miller. “Testing and reporting has shown flower trimmed with the Mobius M108S Trimmer retains more overall terpenes and cannabinoids than hand-trimmed flower.”

The difference, he said, is due to the M108S’s precision engineering. The flower has more than 50-percent increased access to the blades, allowing for a closer trim with significantly fewer human touchpoints than manual processing. The result is a more consistent and gentle cut. The machine’s tumbling action also allows cultivators to process flower continuously at scale instead of one bud at a time as hand trimmers would.

Turning unpredictable expenses into predictable savings

Labor remains one of the largest and most unpredictable expenses for cultivators. Recruiting and retaining skilled hand-trimmers is becoming more difficult as the market contracts. Peak harvest season can put cultivators in a bind, forcing them to rely on temporary workers who may not deliver consistent results. Automation provides a way out of this cycle by replacing variable human labor with predictable, reliable equipment built for performance.

“Mobius has created a tool to help operators determine their potential ROI based on harvest size and current hourly rate,” Miller said. “Using our helpful savings calculator will assist in providing a benchmark ROI and understanding the difference in cost between employing a staff of hand-trimmers versus the automated Mobius Trimmer. Depending on production volume, the trimmer can pay for itself in as little as one harvest.”

Beyond payroll, automation also reduces “hidden” expenses. Costs like personal protective equipment, security measures, and the challenges of maintaining consistency across large trimming teams can add up quickly. With automation, cultivators eliminate much of this variability and gain more predictable, reliable performance.

Timing harvests with precision

While cost savings may be the most obvious benefit of automation, timing can be just as critical. Sourcing skilled and reliable hand-trimmers at scale is a major challenge for producers, especially during peak harvest. Delays in lining up labor may force cultivators to wait longer than they’d like to harvest, risking potency loss in their flower. On the other hand, rushing flower through the process when labor happens to be available can compromise quality.

Automation removes those scheduling hurdles. Instead of being bound by worker availability, cultivators can harvest when flower is at its peak and process it immediately. That means stronger product quality, less degradation, and a more consistent flow of material through the supply chain.

Miller put it this way: “Producers are able to more accurately time their harvests and production schedules with a standardized automated approach, allowing for a consistent flow of product for distribution and sale.”

For many operators, this standardization mirrors what’s seen in other agricultural or manufacturing industries: a reliable production rhythm that gives better control over inventory, distribution timelines, and profitability.

Streamlined workflow and reduced waste

In addition to cost and timing advantages, automation helps preserve yield by reducing product loss from contamination or over-handling. The standardized cut of the M108S ensures uniformity across every bud, and its continuous-flow tumbler gently moves flower through the trimming process with minimal disruption.

Without a large team of hand trimmers to manage, operations teams can focus their energy where it matters most. “Without a large team of hand-trimmers to manage, your dedicated staff becomes more engaged and the workflow is streamlined,” Miller said. “You’re able to employ a more skilled team for quality control and machine operation.”

Staying ahead in a tightening market

With the industry facing increasing pressure from regulatory changes, tight margins, and competitive markets, automation is no longer optional; it’s strategic. Mobius helps cultivators safeguard product quality, reduce operating costs, and accelerate ROI, all while creating more resilient operations. For operators ready to future-proof their facilities, the path to profitability is clear: automation that pays for itself.

Operators who would like to see Mobius’s automated trimmers in action may visit the company’s Las Vegas facility for a VIP demo of the full automation suite.

Mobius Trimmers: Essential FAQs

How does Mobius automation preserve flower quality compared to hand trimming?

Independent testing shows the Mobius M108S Trimmer retains more terpenes and cannabinoids than hand-trimming, thanks to precision engineering that reduces bud handling and delivers a consistent, gentle cut.

How quickly can the Mobius Trimmer pay for itself?

Depending on harvest size and labor costs, Mobius automation can deliver ROI in as little as one harvest, significantly reducing reliance on seasonal or temporary labor.

What hidden gains does automation provide cultivators?

Beyond labor savings, automation reduces product loss from over-handling, ensures consistent harvest timing, and streamlines workflow, boosting overall profitability.

Why is now the right time to invest in automation?

With tightening margins and increasing regulatory pressure, automation is becoming essential for long-term competitiveness, consistency, and financial sustainability in cannabis cultivation.