The latest technologies developed by the industry’s leading manufacturers are helping

cultivators transform products once infamous for their flaws into craft commodities capable of demanding high retail prices and attractive margins.

When the recreational cannabis industry was new, pre-rolls were notorious among consumers for their low price, poor flower quality, and the high chance of burning unevenly or canoeing. As a result, the notion of a high-quality or top-shelf pre-roll was an oxymoron. However, through evolution in automated, high-precision industrial cone grinders and filling machines, the pre-roll market has been reborn. Many pre-rolls on the market today are in-demand products filled with high-grade strains, prepared without human error, and adorned with potent specialty elements like live resin and kief.

Pre-rolls are the second-largest growth category among all cannabis products, and U.S. sales doubled in both 2020 and 2021. There are more than 600 pre-roll labels operating throughout the country without any single brand commanding more than 3 percent of the market, according to New Frontier Data. Automated post-harvest processing machinery, like the all-new Mobius M60 commercial cannabis grinder and hemp mill, can help businesses claim a valuable spot in the still-up-for-grabs pre-roll market.

Automated equipment systems like those created by Mobius have helped revolutionize the pre-roll sector with fully integrated production lines that include industrial grinders, buckers, trimmers, conveyors, and sorters. “The precision of the M60 Mill is evident in the high-quality grind of the cannabis. Cultivators are able to produce an ultra-consistent particle size while maintaining maximum potency and trichome levels. Delivering consistent quality generates significant cost savings from labor and operating expenses as well as product losses,” said Emma Levine, marketing coordinator, Mobius.

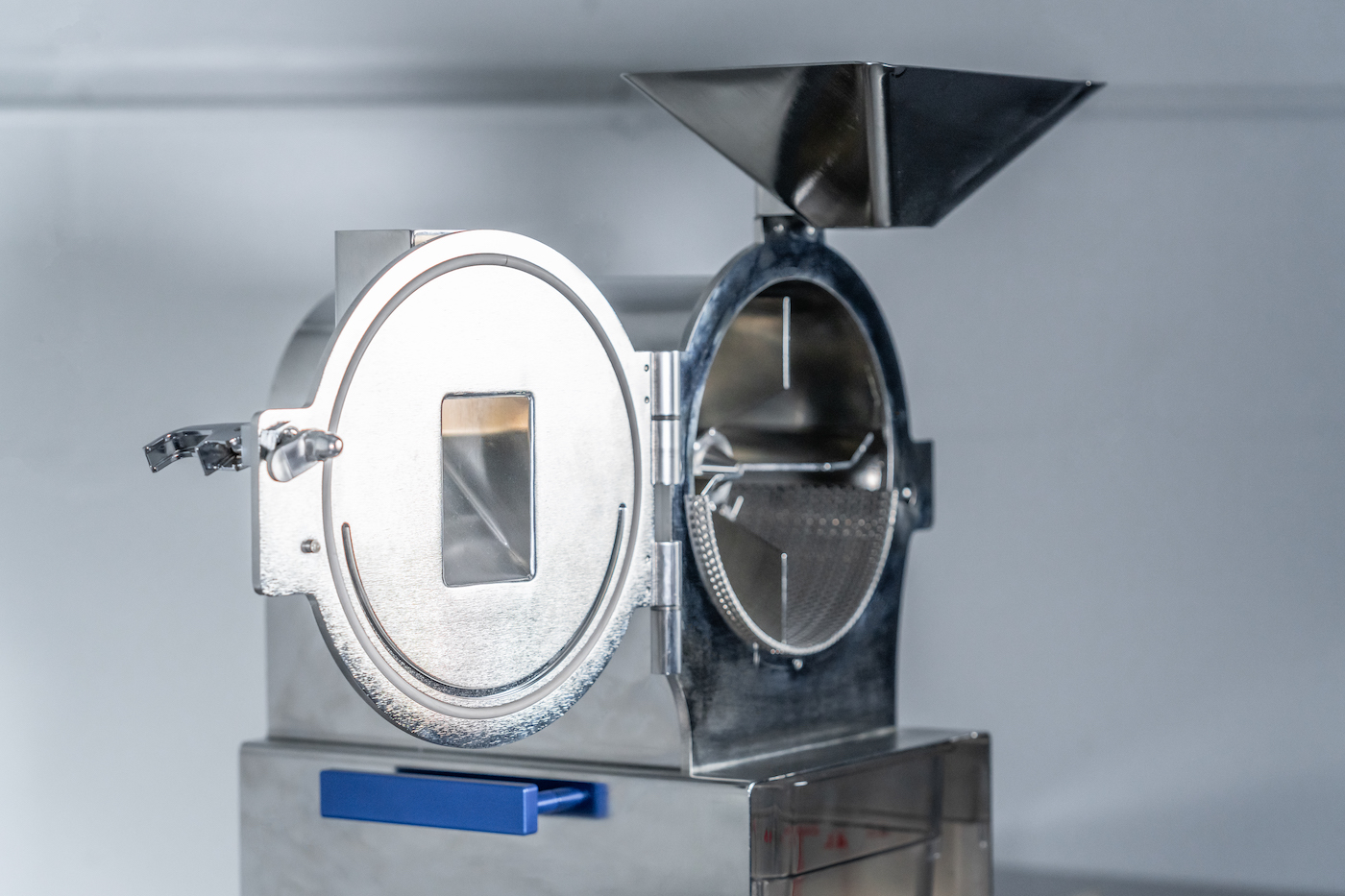

The M60 compact cannabis mill was designed to help companies expand their operations into the growing pre-roll market. Modeled after the Mobius M210 commercial cannabis grinder that can process up to 200 dry pounds per hour, the M60 has an output of 20 pounds per hour in its tiny footprint of only 13 x 16 inches — a significant size reduction from the M210. Both mills are purpose-built with interchangeable precision milling screens to provide maximum trichome retention at any particle size, making them suitable for cultivators of many sizes.

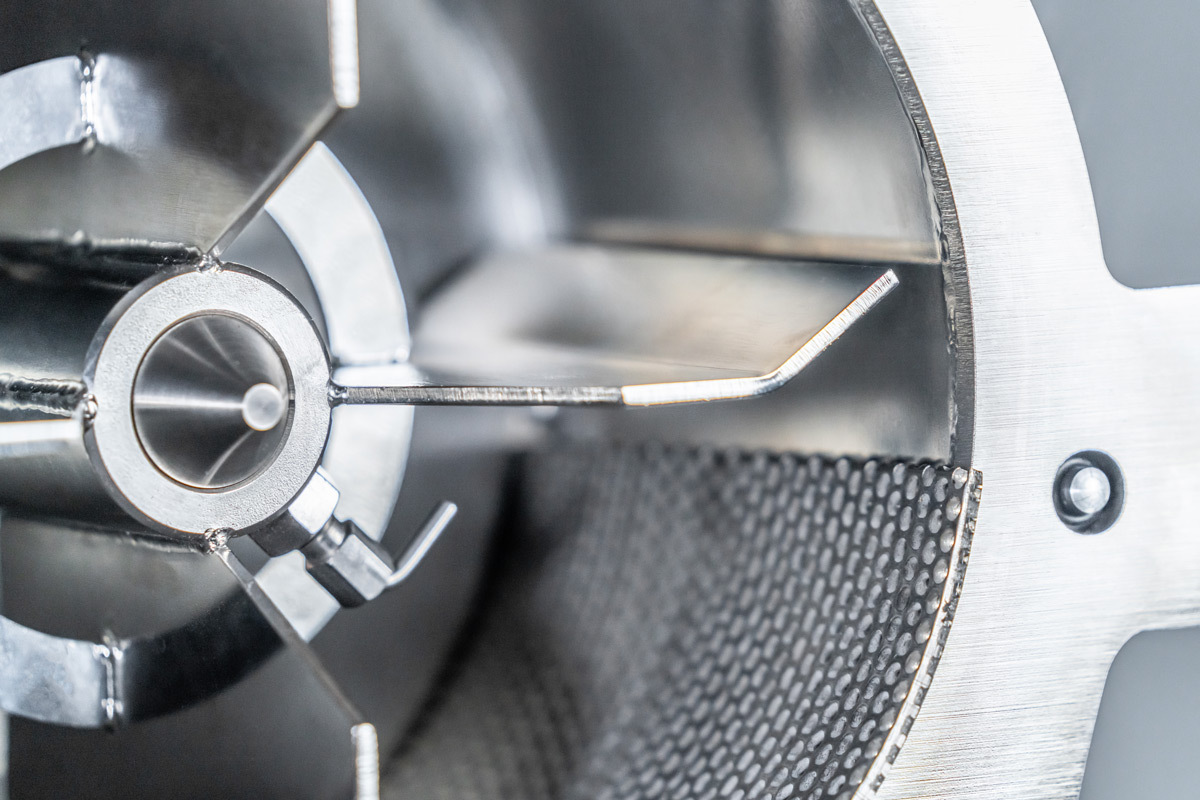

The Mobiusline of high-tech mills features unlimited screen configurations, variable speed operation, and ultra-low-speed motors, all of which contribute to the precision of the grind with consistent particle sizes. The rasp screen paired with the low speed of the motor minimizes heat degradation by maintaining low levels of friction and heat during operation. By using the additional milling screens for coarse chunking and operating in a cryogenic environment, businesses can deliver quality fresh-frozen products with robust terpene profiles. The interchangeable screen sizes allow customization to any grind size for the perfect match with any pre-roll machine.

The M60 is made in North America from heavy-duty stainless steel and features tool-free disassembly, making it easy to clean or swap screens quickly. According to Mobius, operators can have the M60 completely cleaned by hand or with a power washer in fewer than 15 minutes. The features that make the M60 easy to clean and maintain also make it safe: The M60 is equipped with a glove-friendly control panel, emergency stop button, safety interlock on the access door, and tool-free screen removal. Mobius machines are also CE Certified and compliant with General Manufacturing Practices (GMP) and the Certified Senders Alliance (CSA).

The M60 is the latest addition to the Mobius Automation Suite designed to help businesses establish a foundation for growth, create a faster speed to market, and reduce human error. Integrable equipment systems can drastically reduce trim-room labor, operating expenses, employee turnover, and training costs. Safari Flower Co., a Mobius customer, reduced its time to market and increased cash on hand by 25 percent after implementing the Automation Suite.

Mobius is confident in the technology it produces and wants customers to feel comfortable investing in equipment, whether it’s a singular hemp mill or an end-to-end automated system. Mobius machines include a 100-percent money-back guarantee and specialists are available to assist with automation planning.

At a time when pre-rolled cones are essential to many cannabis manufacturers, it is vital those businesses receive the ongoing customer service needed to produce consistent products. Mobius demonstrates its commitment to customers by offering free design consultations and planning services for those considering an Automation Suite. After a specialist trains customers on equipment operation and installs the equipment, Mobius remains an accessible resource. Whether two months or two years from the purchase date, Mobius technology experts are available to help customers troubleshoot and continually optimize production systems.