Air filtration within cannabis grow operations does more than make the environment a more pleasant place in which to work. It literally can prevent unsafe working conditions and ensure plant health.

Indoor cannabis grows allow for cultivation just about anywhere despite the outdoor climate. The obvious advantage to growing indoors is being able to create the perfect conditions for optimal yields. Indoor cultivation also offers growers a wider range of strain diversity, since no outdoor climate is optimal for every strain.

However, when you bring the outdoors inside, some challenges also enter. Maintaining proper air quality, for example, can be difficult. Grow rooms may not always have the best ventilation, trapping pollutants and humidity where they shouldn’t be.

Although maintaining the ideal indoor growing environment can be challenging, it’s not impossible.

High-quality air filtration can decrease levels of pathogens including mold spores like botrytis, powdery mildew, and fusarium. According to a study conducted at Simon Fraser University, pathogens can have a severe negative impact on cannabis plants’ growth. This can restrict yields, compromise the quality of the harvest, and create compliance headaches — all of which may harm the bottom line.

Obviously, concerns extend far beyond just compromised plants and a corresponding loss of revenue. Air filtration in indoor cannabis grows also can prevent harm to cultivators. Working inside a grow facility increases exposure to volatile organic compounds (VOCs) through the eyes, skin, and respiration. VOCs are chemicals that vaporize and are absorbed by the air. They are found in many consumer products including paint, cosmetics, and cleaning agents. Consumers often recognize them as fragrances or odors. Terpenes, the fragrant compounds that give cannabis its distinct aroma, are VOCs. While terpenes and many other VOCs are harmless in most instances, they can become toxic in the large concentrations sometimes found in indoor cannabis grows. Reducing terpenes through filtration is crucial in providing a safe environment for cultivation workers.

In January 2022, Trulieve employee Lorna McMurrey suffered a fatal asthma attack at a cannabis production facility in Holyoke, Massachusetts. Although Truelieve maintains the facility had adequate air filtration, the state’s Cannabis Control Commission (CCC) claimed the site did not comply with safety regulations.

The company agreed to pay a $350,000 fine to the CCC and a $14,500 penalty to the federal Occupational Safety and Health Administration. In a pending lawsuit, McMurrey’s family alleges she had an asthma attack on the job prior to the fatal incident. The lawsuit claims Truelieve failed to address airborne cannabis dust, mold, and other particles emitted from pre-roll processing machines.

Truelieve has not admitted fault and only briefly commented publicly about the situation.

“Trulieve will continue to operate its facilities in a manner that fully protects the health and safety of all employees,” the company stated in 2022. “We are confident we did so in January and will continue to do so going forward.”

Cultivators are not the only ones at risk. In 2017, a highly publicized report highlighted the dangers of contaminated cannabis for patients. Dr. George Thompson at the University of California, Davis, works with patients suffering from fungal infections. He took note of a pattern occurring with cancer patients who had weakened immune systems and pneumonia-like symptoms from fungal infections. All of the patients were treating pain symptoms with medicinal cannabis.

“We thought it was strange to have cases of such a bad fungal disease in such a short amount of time,” Thompson told CBS News.

Thompson and his team sent twenty samples of medicinal cannabis, from twenty different California dispensaries, to a laboratory. Almost all samples tested positive for bacteria and fungi. Although the contaminants the labs found typically are harmless to individuals with a strong immune system, they could be fatal to populations closely associated with medicinal cannabis use, including patients receiving chemotherapy. One of the patients died, and his death is thought to be related to contaminated cannabis.

Testing regulations have become stricter since 2017.

Grow room workers and consumers have an obvious stake in safe cannabis cultivation, but proper filtration also may fend off another common issue: neighbor complaints. Although emissions from commercial grows are small when compared to other industries, the cannabis industry is considered a top-ten source of VOCs in metropolitan areas that have legalized production, sale, and use, according to the American Chemistry Society (ACS). Unfortunately, despite other industries posing larger risks, ACS research found cannabis cultivation facilities receive significantly more nuisance complaints than many other industrial centers, including sewage treatment plants.

It’s imperative industry leaders, business operators, and regulators ensure cannabis cultivation operations not only produce high yields, but also offer safe work environments, effective medicine, and pleasant living conditions in their communities. Deploying effective air filters is one way indoor cannabis grows can achieve those goals. Among the two most effective options are high-efficiency particulate air (HEPA) filters and carbon filters. Using both HEPA and carbon filters typically is recommended for cannabis grow operations to maximize safety for workers and consumers.

HEPA filters are made of woven fibers and designed to catch airborne particles before they can be breathed in. HEPA filters can eliminate up to 99.9 percent of airborne particles like dust, pollen, mold, and viruses.

Here are three brands professional cultivators use and recommend.

Advanced Filtration Concepts HEPA filter

HEPA Filters offered by Advanced Filtration Concepts are designed specifically for critical applications that require high-efficiency particulate air filtration. Key benefits include:

- Mini-pleated, wet-laid microglass.

- Extended media area.

- V-bank-style media packs.

- High-efficiency filtration (99.99 percent).

HEPA filters, on their own, are not able to filter out odor, gasses, and VOCs effectively. This is where carbon filters come in. Carbon filters are packed with activated charcoal and target VOCs including cannabis terpenes and gasses. They help protect both plants and cultivators. They also may eliminate odors from the grow facility that cause complaints from the local community.

TerraBloom carbon filter

TerraBloom carbon filters use high-grade, granular Australian activated charcoal, which captures odors, VOCs, and other airborne pollutants. TeraBloom’s charcoal scrubber can be installed both inside and outside the grow area and is capable of filtering air in both directions.

According to TerraBloom, its carbon filters:

- Have a 1.8-inch (46mm) deep carbon bed.

- Do not use low-grade pelletized carbon rods.

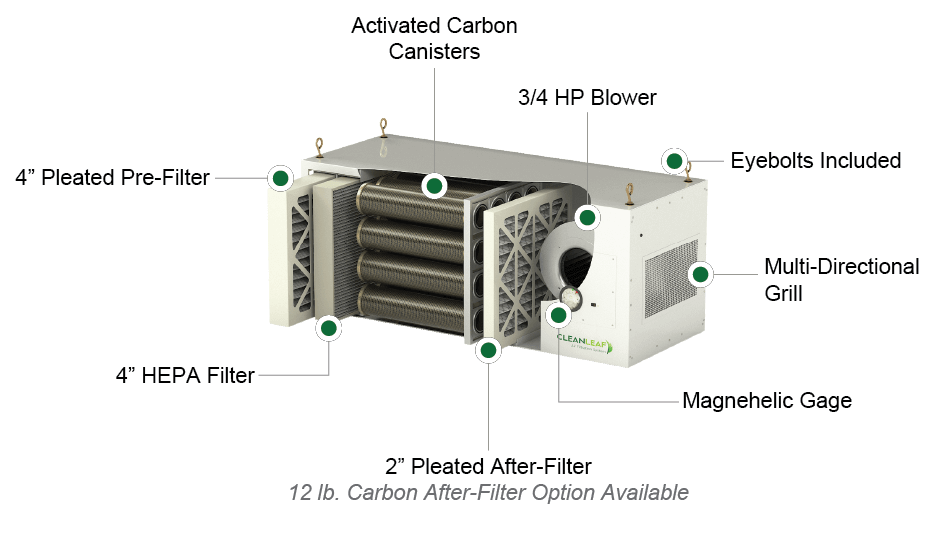

CleanLeaf all-inclusive series

Those seeking a single product that combines both HEPA and carbon filters may want to consider the CleanLeaf All-Inclusive Series. The products help cultivators eliminate odors while protecting plants from grow-room threats like bacteria, mold, and mildew.

The All-Inclusive Series offers:

- HEPA-saving pre-filter fiber media.

- A 95-percent-efficient dispersed-oil particulate filter.

- An odor-absorbing carbon canister and a pleated after-filter.

- Effective filtration for approximately 15,000 cubic feet.