Product packaging is an extremely important element in expressing a brand. Consumers touch and feel it, they judge it, and they form a deeper relationship with the brand through the unboxing experience.

As most business owners and brand managers know, the quality of a product’s packaging can have a direct impact on sales and reflect upon the brand’s image. Higher-quality packaging implies the product will be of the highest pedigree, while inferior packaging sends the signal the product will be of lower quality. Studies have shown 70 percent of buying decisions are influenced by a product’s packaging. Moreover, the quality and type of packaging affect consumers’ trust in the product.

Over the past several years, I have witnessed a wrapping revolution in the cannabis industry. We’ve come a long way, and much of the industry now offers very sophisticated and thoughtful packaging design.

As you develop or refresh your brand, the right visual merchandising can help you impress consumers and compete with major players. Here are some trade secrets and best practices to set you up for success, starting with the three main elements to consider in any project: paper, coatings, and finishing/decorating.

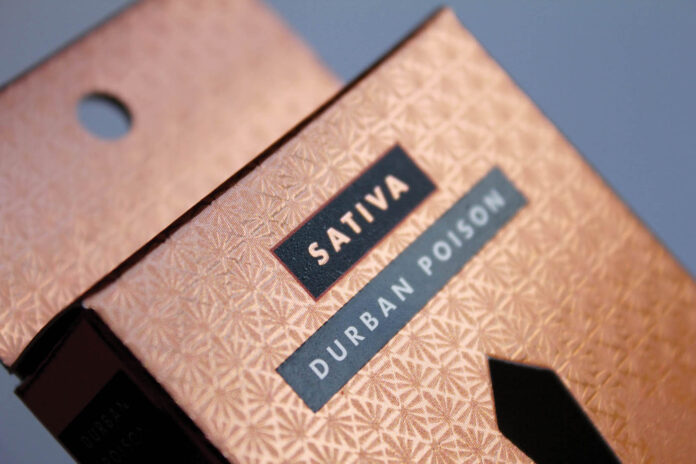

The lion’s share of all packaging is produced on solid bleached sulfate (also known as SBS) paper. It’s the standard of the industry due to its affordability and good printing surface, which is conducive to decoration. However, there also is a vast selection of more expensive specialty papers. An uncoated kraft stock may be the perfect choice for a natural brand, while a pearlescent/shimmery stock or a foil board may create a more sophisticated look.

The stock chosen lays the foundation of the package.

Laminations and coatings

Coatings are used to protect packages from scuffing or offsetting and to accentuate and enhance the container. Adding contrast to the surface of a package creates visual interest that can elicit specific responses from consumers.

A lamination is a piece of film bonded to the stock, providing the very best protection against cracking, fingerprinting, and scuffing. Laminations come in several finishes: matte, dull, gloss, and soft-touch. This type of effect is more expensive than inline coatings such as aqueous coating (AQ) or UV.

Way back in the day, everyone used varnishes to coat and protect projects, but this method required an extra plate on the press and longer drying times, so the aqueous coating was born. AQ is a clear, fast-drying, water-based coating used to protect printed pieces. It provides a high-gloss, matte, or soft-touch surface that deters dirt and fingerprints.

Spot-gloss UV, one of the most popular treatments used in packaging, draws consumers’ eyes to the treated areas — often a logo, product name, or tagline. UV coatings provide a superior high-gloss finish and offer the highest degree of contrast. UV also comes in the same variety of finishes: high-gloss, matte, dull, and soft-touch.

An impressive way to add a tactile and more dramatic effect is by using a raised UV coating, which adds dimension that can accentuate portions of the packaging and invite consumers to touch the surface.

A variety of other coatings are used more rarely, including glitter, pearlescent, metallic, and reticulating. If you want a luxurious, shimmering appearance, then a pearlescent coating or glitter UV might be the right solution. Metallic sheens like silver and gold not only convey an image of wealth and sophistication but also deliver a look similar to foil stamping at a fraction of the cost. One of the most dramatic coatings is achieved through a process called reticulation, which creates an interesting visual effect by carefully combining both a spot varnish and an overall UV coating.

Decorating textures

Textures also can give packaging a unique and distinctive look. Here are a few:

Embossing and debossing: Raising and depressing packaging areas provides an interesting effect that historically has been used to signify elegance and luxury.

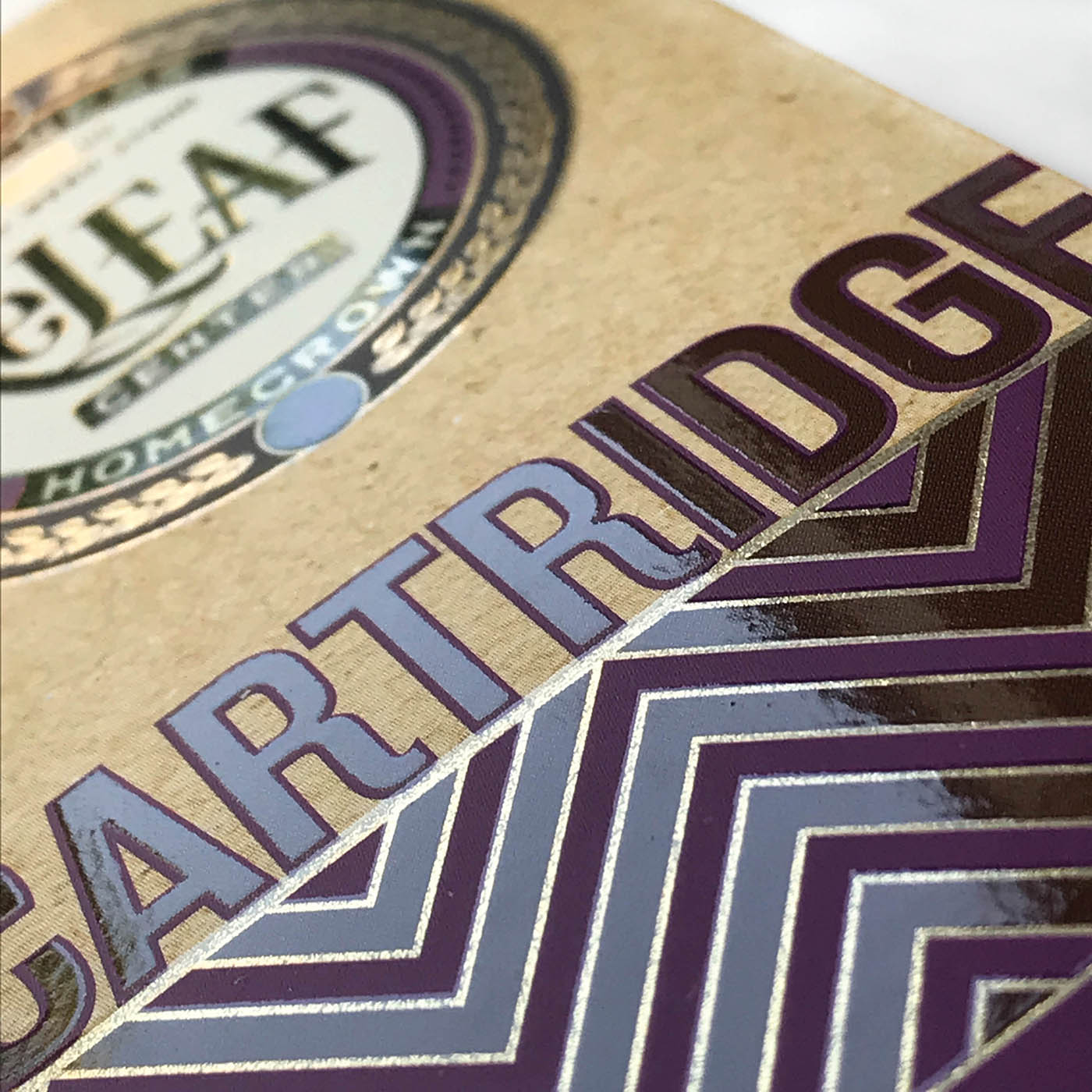

Hot foil stamping: This stunning effect has been used for hundreds of years. Some early manuscripts used real gold leaf to decorate intricate calligraphy, and the most beautiful and expensive books often were embellished with real gold leaf. The technique produces a highly reflective image with a bright and alluring metallic appearance.

Cold foil printing: Unlike hot foil stamping, which requires a specialized foil-stamping machine, this process can be done on a press. Foil is dispensed from a roll, and an ultraviolet lamp cures an adhesive and locks the design in place. Cold foil is the preferred technique for larger areas and can be customized by applying color to traditional silver or gold foils.

Digital foil printing: Digital foil printing is a bit easier and cheaper to produce, as it is printed directly from a computer file and requires no dyes. The result is smooth, ultra-shiny, and often raised like an embossed piece but at a fraction of the price.

These are just a few of the many techniques that can take packages from ordinary to extraordinary. Packaging is more than just a way to protect your products. It’s an important sales tool and a vital representation of your company and brand.

Photos: Hippo Premium Packaging

[…] days of the nondescript sandwich bag or film canister. Contemporary dispensaries are filled with boxes featuring ornate embossed lettering, 3D-printed containers in wildly unusual shapes, and recycled plastic containers that promise a […]

[…] The right packaging can convey a sense of quality, sustainability, and social responsibility. Brands that prioritize sustainable packaging, upcycling, and recycling can attract environmentally conscious consumers and reduce their carbon footprint. […]

[…] values that extend to the product itself. At the end of the day, consumers want an experience, and packaging is an important facilitator in achieving that […]

[…] course, there’s a lot more to designing perfect packaging for consumer packaged goods than merely creating a beautiful outer shell. Packaging also must […]

[…] with a footprint in seven states. “Regional representatives typically use tables, tents, photos, packaging of products, uninfused products, and dialogue to form personal connections. The idea is to make the experience […]