Who says the mortgage industry is cursed? Scott Martin was a very successful mortgage broker until his company merged with a larger firm in 2013. During the merger, Martin met a client who owned a patent for canning ammunition in a hermetically sealed container with a modified atmosphere.

Martin was intrigued. The two began discussing a patent he had filed that duplicated the ammunition patent for the packaging, storage, and preservation of controlled substances. “We negotiated a partnership, and in 2014 we worked together to receive the patent,” noted Martin. “N2 Packaging was born and is now my primary focus.”

Martin adapted to the cannabis industry with the flexibility and patience he learned in the mortgage industry. In fact, N2 changed its business model multiple times to suit the reality of the cannabis market. While Martin likes to strive for a lean, efficient operation, N2 is growing to meet demands. He oversees fifteen full-time employees in the United States and Canada.

“We felt this would be a beneficial solution for growers because it would remove shelf life concerns from their business model,” he said. “We thought consumers would appreciate the consistently fresh quality of the product that was associated with the N2 brand.”

The process has not been without obstacles. Because consumers were accustomed to buying cannabis in a clear bag they could open and smell, N2 received significant negative feedback about the inability to “see it, touch it, feel it” before purchase. “We often heard `I’m not putting my weed in a cat food can,”‘ he noted with a chuckle. “We have worked on solutions to these hurdles but still occasionally hear the same concerns. With time, people are beginning to see the quality and consistency our product offers, and they are changing their thinking.”

WHAT MAKES N2’S NITROGEN CANS UNIQUE?

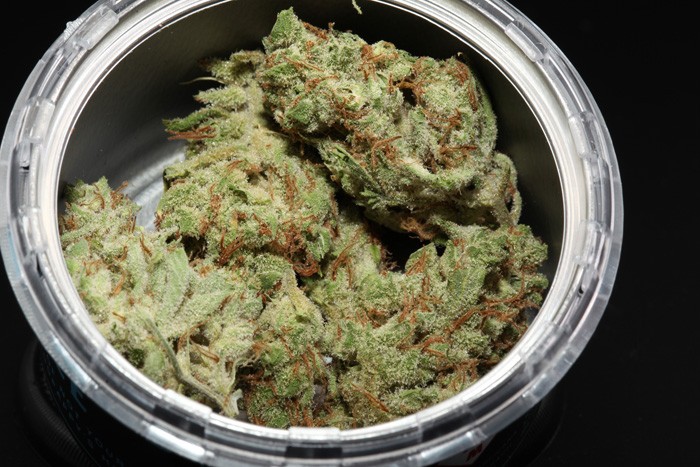

The main culprit of degradation in cannabis is oxygen. Remove oxygen from the equation, and that creates a time-capsule-like effect. Our patented process flushes the can with liquid nitrogen—a very small amount—which bounces off any solid object, essentially burning off in the can while pushing the oxygen out. After that happens, the can is hermetically sealed, creating a perfect, modified atmosphere: no oxygen, no light.

Nitrogen is most commonly known as an inert gas. Since the cans’ atmosphere is rid of the oxygen, the cannabis flower is safe from any mold, microorganisms, and bacteria. The master growers I grew up learning from used nitrogen to preserve their flower. Our process gives you the opportunity to preserve your flower until you are ready to push your product, or until the price is right. Extended shelf life is key for this industry. On top of that, the N2 process provides a dream to cultivators: farm-to table-freshness; good in, good out. What you cure and put in the can is how the consumer will receive it.

THE CANS ARE TAMPER-PROOF, RIGHT?

We are particularly proud of our child-resistant, resealable-lid option. I became very concerned about the childproof requirements that initially rolled out in Colorado, and I immediately began working on a solution. We searched everywhere to find a childproof lid but discovered there had never really been a need for a childproof lid to reseal a can, so there was nothing out there. We knew this would be key to remaining compliant, so we spent ten months designing a lid that would meet the child-resistant and senior-friendly requirements. These are all-important features that make N2 a unique and practical way to package cannabis.

WHO IS N2’S CORE CONSUMER?

We deal with just about everyone, but at the core is the cultivator. The opportunity for growers to package in-house is a pretty incredible thing. Presentation is a major factor for any type of retail. Having this professionally packaged flower, and wrapping it in your very own marketing, brings a bigger sense of ownership to brands. The can fits in your hand perfectly. There’s something about it people gravitate toward.

HOW’S BUSINESS?

We made a few key decisions in 2017 that will help us greatly in 2018. The first was to purchase the equipment company that has been supplying all of our systems, which has allowed us to control our growth and the process. Second, we contracted to manufacture our own cans to control our inventories, and third, we have two fulfillment centers—one in Arizona, and one in Twin Falls, Idaho. We receive approximately fifteen license applications per week from facilities all over the world. Having the ability to scale will greatly help us to fulfill those requests.

WHAT HAVE BEEN YOUR GREATEST CHALLENGES?

One of our first big hurdles was gaining consumer acceptance and getting consumers to think beyond the “see it, touch it, smell it” concept. We still struggle with that in some states, but we have worked hard to make sure any product branded with the N2 logo is a high-quality product from a reputable, licensed grower. Quality control is paramount to our process. Another huge obstacle has been dealing with the same issues everyone in the cannabis industry is facing: trying to operate legally despite the opposing state and federal laws. Many suppliers either won’t work with us or raise prices to cover “additional risk” of working in the cannabis industry. We’ve had all of our business and personal banking accounts shut down multiple times because of conflicting laws and regulations.

Whenever possible, I remain actively engaged in meetings with legislators and lawmakers to provide input and stay on top of the evolving rules and regulations of the industry.

WHAT’S A TYPICAL DAY LIKE AT N2?

I like to get to work at 8 a.m., make calls, do orders, etc. Then I like to meet with staff. I live in Idaho and I operate out of our Idaho fulfillment center, but our company headquarters are located in Scottsdale, Arizona. Unfortunately, that means I spend a lot of time on the phone and a lot of time in airports. I typically travel three days a week to meet with current and potential clients.

There is no such thing as 9-to-5 Monday through Friday office hours for me. If I’m awake, I’m working. It has been a grind, but everyone at N2 is pushing hard to build our company, and I love being part of it.

WHERE DO YOU SEE N2 HEADING IN 2018?

I see us continuing to grow into the more heavily regulated U.S. and Canadian markets. We will also continue to look for advancements with our packaging. We will be rolling out our Clear Can at the end of the first quarter and our Clear Lid for the metal can by the end of the year. —Rob Hill