The phrase “family business” often brings to mind heritage, legacy, and stability, and Hefestus embodies all three. Based in Israel and serving the global cannabis market, the third-generation engineering house is rooted in a tradition of agility and innovation.

This fall, the company is introducing two proprietary technologies poised to reshape how infused pre-rolls are made and kept fresh.

Patented “donut” infusion for smoother, cleaner draws

Infusion has become a major value driver: Consumers want concentrate-level potency with a familiar smoking experience. Brands often saturate biomass with full-spectrum distillate or inject concentrates like rosin or budder into joints, but those methods can cause clogging, uneven burn, or poor draw. Kief-coating, or “stardusting,” is typically manual and inconsistent.

Hefestus’s answer is a patented inside-out “donut” infusion method. Instead of pushing concentrate into the center of a pre-roll, the joint is engineered with a tiny airflow channel through the core. The result is consistent burn and a smoother draw without clogging, canoeing, or sacrificing smokability at higher infusion levels.

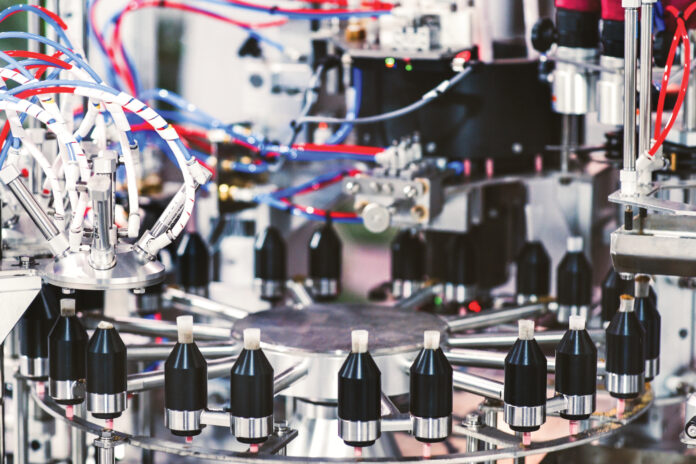

The new donut-making equipment provides a fully automated, scalable solution compatible with multiple formats including pre-rolls, blunts, and cones. Simple in concept but bold in execution, the system reflects Hefestus’s core strength: bridging high-precision engineering with cannabis manufacturing challenges.

MAP technology that preserves freshness and potency

Even when production is dialed in, distribution presents its own obstacles. Flower and pre-rolls are highly sensitive to oxidation, humidity, and terpene loss. In food and pharmaceutical packaging, modified atmosphere packaging (MAP) is widely used to mitigate those issues but cannabis has been slow to adopt it.

Hefestus’s MAP system flushes ambient air from packaging like tubes, jars, and multipacks and replaces it with inert gases like nitrogen, dramatically reducing oxygen and humidity. The benefits: mold prevention, terpene preservation, and maintained potency. In short, what ships out is what consumers experience after purchase.

“Once flower is ground and rolled, protective packaging becomes even more critical,” said Hefestus USA Chief Executive Officer Shahar Yamay. “Proper MAP sealing helps ensure the pre-roll a customer lights is as fresh as the one that left the production line.”

The process is both elegant and robust: After a pre-roll is inserted into its package, the system flushes, seals, and safeguards the internal atmosphere while still allowing for labeling and visibility. It transforms packaging from a container into a quality-preservation system.

Automation that scales with modern cannabis operations

In cannabis manufacturing, automation is no longer optional. Brands relying on manual labor for filling, infusion, and sealing face higher costs, inconsistent quality, and limited scalability. With decades of automation experience across food, pharma, and consumer goods, Hefestus brings proven precision to cannabis operations.

“We stay ahead of the game, we listen to our customers, and we adjust in real time,” said Head of Business Development Tomer Oliel. “Our goal is to strengthen our customers’ success through innovation that’s practical and reliable.”

With technical rigor and real-world usability, Hefestus helps producers deliver consistency, smoother experiences, and longer shelf life—engineering progress without losing sight of its roots.

The science behind better pre-rolls

What is Hefestus’s donut infusion technology?

Hefestus uses a patented airflow channel at the center of the pre-roll, enabling higher infusion levels without clogging, canoeing, or uneven burn.

How does MAP sealing keep pre-rolls fresh?

The system replaces oxygen with inert gases to reduce humidity, mold risk, and terpene loss—maintaining the product’s intended experience.

Why should pre-roll manufacturers automate?

Automation reduces labor costs, ensures high-volume consistency, and supports regulatory-grade repeatability that hand-filled processes can’t match.

For what industries has Hefestus engineered?

The company brings decades of automation expertise from food, pharma, and consumer goods—now adapted for cannabis production.