As solventless concentrates surge in popularity, cultivators and manufacturers are racing to refine their processes — or risk getting left behind. Projected to command a significant share of the $73-billion global extract market by 2034, solventless products offer what today’s consumers crave: high-purity, chemical-free concentrates that preserve the plant’s native profile.

Unlike solvent-based techniques, which rely on chemicals like butane or ethanol, solventless processes — ice-water extraction for bubble hash or heat-and-pressure methods for rosin — emphasize mechanical separation to isolate trichomes, cannabinoids, and terpenes.

| Metric | Solvent Extraction (BHO/CO2) | Solventless Extraction (Rosin) |

|---|---|---|

| Initial CapEx | High (C1D1 labs, blast proofing) | Lower (Presses, wash systems) |

| Average Purity | 70% – 90% | 85% – 99% |

| Yield Efficiency | Very High | Moderate to High |

| Retail Premium | Standard | 20% – 50% Higher |

| Safety Risk | High (Flammability) | Negligible |

But scaling these artisanal methods to commercial production isn’t easy. For operators looking to increase yields, improve consistency, and stay compliant without sacrificing quality, optimizing the workflow is no longer optional; it’s essential.

From material preparation to environmental controls, facility design, and processing techniques, here’s what cultivators need to know to navigate their current operations and prepare for future scaling.

What is the best starting material for solventless extraction?

The quality of solventless extracts begins long before extraction with meticulous material preparation. Fresh-frozen cannabis, which is flower harvested at peak ripeness and immediately frozen, is ideal for preserving trichome integrity and terpene content. Studies show cannabis flower frozen within hours of harvest retains a much higher level of volatile terpenes than flower preserved using traditional drying and curing processes.

Particle size is a critical factor. For bubble hash production, which often serves as the input for hash rosin, agitation in ice water separates trichomes, followed by filtration through micron bags. The optimal micron range for premium hash is 73–120 microns, capturing mature trichome heads with the best oil-to-cuticle ratio. Bags below 73 microns may collect immature heads or debris, reducing purity, while larger sizes (160–220 microns) increase yield but introduce contaminants like plant matter.

Milling dried flower for direct pressing (flower rosin) requires precision to avoid heat buildup, which degrades terpenes. Research indicates milling at temperatures above 50°F (10°C) can lead to resin smearing and trichome loss, while cooler conditions — around 40°F (4°C) — maintain brittleness for cleaner cuts. Uniform particle sizes enhance surface area exposure, improving cannabinoid release without releasing unwanted compounds like chlorophyll.

Best practice: Conduct small test batches to assess resin content and adjust milling parameters. For repeatability, use perforated screen mills over blade or hammer types, as perforated screen mills produce consistent particles with minimal friction. This not only boosts yields but also ensures batch-to-batch consistency, a key metric for regulatory compliance and market positioning.

What is the optimal temperature for terpene preservation?

Environmental factors in the processing room directly influence extraction outcomes. Temperature and humidity must be tightly controlled to prevent degradation and microbial growth. Ideal conditions for the processing room hover at 60–70°F (16–21°C) with 50–60 percent relative humidity (RH), while extraction rooms should be kept much cooler for processes like hash washing.

Water activity (aw) — a measure of free water available for microbes — should stay between 0.55 and 0.65 to inhibit mold while preserving moisture for terpene retention in dried flower. High aw risks contamination, potentially leading to product recalls, while low levels cause brittleness and potency loss. Moisture content, typically 10–12 percent, complements this by ensuring pliable material that doesn’t degrade during handling.

In drying and curing phases post-harvest, maintain 55–60 percent RH to allow even moisture redistribution. Over-drying can evaporate terpenes (some as low as 70°F boiling points), reducing aroma and efficacy. Conversely, high humidity fosters oxidation, converting cannabinoids to less-potent forms like CBN.

How can facility layout improve production efficiency?

Facility layout plays a pivotal role in scaling solventless operations. Poor material flow can lead to bottlenecks, increasing labor costs, and contamination risks. Design with a linear progression: move from washing stations for bubble hash to freeze dryers, grading areas, and presses. Separate raw and clean zones to comply with GMP standards, reducing cross-contamination.

Automation enhances repeatability. Hash washing systems with programmable agitation cycles ensure consistent trichome separation, avoiding over-agitation that introduces plant debris. For rosin pressing, stackable presses with precise temperature (160–200°F) and pressure controls prevent degradation. Pre-press molds shape flower into uniform pucks, minimizing blowouts and improving yield uniformity.

The construction and design of the machines impact the quality of the extraction process. Equipment made with stainless steel that is easy to clean and maintain will be crucial for pure extractions and uncontaminated products. More advanced solventless systems feature automatic washing cycles, savable recipes, and precise temperature control.

How do you maximize rosin yield without sacrificing purity?

Solventless methods vary, but optimization hinges on technique. For bubble hash, gentle agitation in cold water (below 40°F) releases intact trichomes. Filtration through different micron bags isolates grades, with full-melt (5–6 stars) commanding premium prices due to superior melt and terpene preservation.

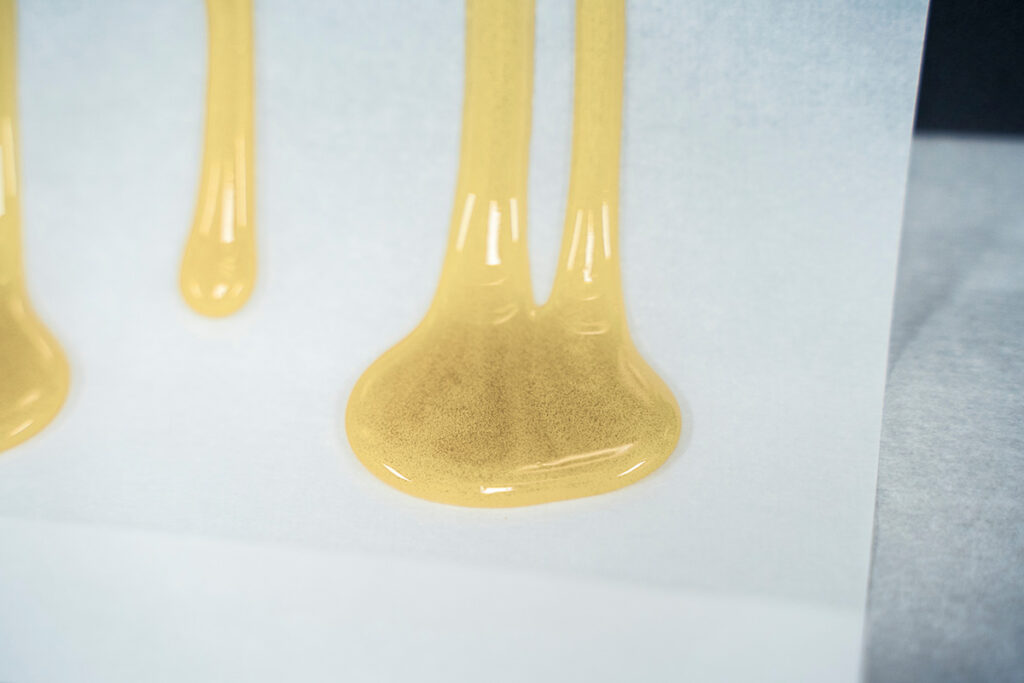

When pressing flower or hash rosin, applying even pressure helps avoid channeling during the process. Test presses dial in parameters per strain; for example, lower temperatures for terpene-rich varieties. To maximize yields without sacrificing quality, account for upstream variables. Fresh-frozen inputs boost overall rosin yields to 2–5 percent from biomass, versus lower yields from dried flower. Grading post-drying ensures only full-melt hash proceeds to pressing, enhancing potency (up to 70–90 percent THC in top extracts).

For consistency, it is important to document SOPs such as agitation times, water purity, and press settings. Training staff on visual cues like rosin color during pressing builds repeatability.

Overcoming common challenges and measuring success

Common pitfalls include inconsistent inputs and environmental fluctuations. Mitigate those challenges by sourcing peak-ripeness material and standardizing preparation practices. Metrics for success can range from yield percentages to potency and terpene testing.

High-quality solventless products fetch top-tier pricing in retail, justifying investments in optimization. Regular audits refine processes, ensuring adaptability to trends like demand for live rosin.

Optimizing solventless extraction demands a holistic approach from precise material prep and controlled environments to efficient designs and refined methods. By prioritizing efficiency, repeatability, and consistency, producers can achieve high yields and superior quality, positioning themselves for long-term success in a competitive market.

The lowdown on solventless cannabis extraction

What is solventless extraction in cannabis processing?

It is a mechanical method using ice, water, heat, and pressure to isolate trichomes and terpenes without chemical solvents like butane or ethanol.

What’s the best input material for solventless extraction?

Fresh-frozen flower is ideal. It preserves the trichome structure and volatile terpene content far better than dried material, resulting in superior aroma and flavor.

How can operators scale solventless extraction processes?

Scaling involves optimizing facility layout, investing in automated equipment with programmable settings, controlling the environment (temperature, humidity, water activity), and developing detailed SOPs for repeatability.

What micron size is best for bubble hash production?

The 73–120 micron range is the “sweet spot” for premium hash. It captures mature trichome heads while filtering out immature heads and plant debris.

What is the optimal temperature for solventless rosin pressing?

For flower rosin, 180°F to 220°F is standard. For hash rosin, lower temperatures (140°F to 180°F) are preferred to preserve volatile terpenes and achieve a lighter color.

How do you maximize solventless extraction yield?

Optimization starts with “fresh frozen” material. Using the correct micron bags (73–120μ) and applying even, consistent pressure during the press ensures maximum oil recovery without plant matter contamination.

Why is environmental control critical in solventless labs?

Cold processing (below 40°F) is essential to keep trichomes brittle for separation. Maintaining 60-70°F and 50-60% humidity in the room prevents terpene evaporation and microbial growth.

With more than twenty years of dedicated experience in equipment sales, Mobius Account Executive Scott Miller has developed a thorough understanding of equipment performance, life-cycle costs, and the practical needs of diverse industries from manufacturing and warehousing to roadwork and infrastructure projects.

[…] Optimize micron strategy: prioritize 73 to 120 micron bags for premium full-melt hash. Larger micron bags raise yield but invite contaminants. See practical micron guidance at MG Magazine. […]

[…] Address challenges with facility design, automation, and strict SOPs. First, design a linear workflow that separates raw and clean zones. In addition, implement environmental controls for extraction rooms to hold 60–70°F for processing and cooler ranges for washing. For facility guidance and case studies, see industry insights at MG Magazine. […]