Product packaging is essential to building and maintaining your brand—no matter if your cannabis business is a start-up or an established business with a dedicated customer following. It is the first thing seen by a potential customer and it creates a critical first impression. While the primary function of any packaging is to contain, protect, and identify your cannabis products, it also is a reflection of your company in the eyes of the customer. In many ways, the packaging is the product. Partnering with a quality packaging manufacturer will increase your chance of success in this emerging market.

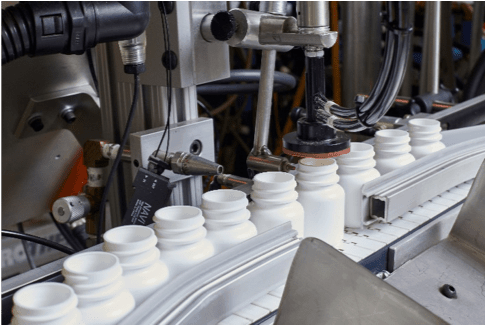

Bottles and closures made of high-density polyethylene (HDPE), low density polyethylene (LDPE), polypropylene (PP), and polyethylene terephthalate (PET) have become widely accepted as a packaging option for the cannabis industry. There are many plastic bottle manufacturers in the market—how do you find one that’s the right partner for you?

Dig deep with the right questions

When you begin the process of finding a cannabis packaging manufacturer that specializes in plastic bottles and closures, it’s important to think about what you want the packaging to say about your brand and your company. Then define what you’re looking for in a manufacturer. Don’t know what to ask? These topics and questions will help you gather the right information to help you make informed decisions.

Can you create custom packaging for my brand?

Does the packaging manufacturer have the capability to customize its products to your exact design and specifications? Your product is unique, and your packaging should reflect that. Make sure your brand stands out with the exact image you want to project. Do they offer engineering services, CAD designs, and quality testing that make your packaging ideas a reality, differentiating your brand from the competition? Is there “depth” in your supplier—can they do more than just sell you packaging solutions that already exist?

Do they have state-of-the-art production equipment, value rigorous process, and practice continuous improvement to ensure dependable product quality every time? Partnering with a manufacturer who understands that bottle defects diminish brand presence and who continually strives to remove defect-producing production problems from its manufacturing process is of utmost importance. This avoids many downstream quality problems and helps to keep the focus on growth and off damage-control. Sub-par plastic bottles and closures can lead to inefficiencies on your filling lines, lost production time, and product that cannot be sold.

Product recalls and safety concerns can be a result of imperfect plastic bottles or material trapped in the resin that makes the packaging look dirty or contaminated. This can also erode consumer confidence in your brand or expose the customer to unnecessary risks. These situations lead to reduced profitability and negatively impact your bottom line. And let’s not forget—packaging defects undermine consumer confidence.

Does your packaging comply with packaging regulations?

The cannabis industry faces more and more complex regulatory challenges every day. Is your packaging being manufactured in compliance with FDA regulations, as well as individual state regulations?

In addition, new regulations are being imposed for child-resistant packaging. Does the manufacturer also produce closures for their bottles, ensuring that the bottle and closure work together to protect your product and comply with strict child safety regulations? Working with a “one-stop-shop”—a manufacturer who produces plastic bottles and closures—allows you to create a completely designed system to protect the product and comply with regulations today and in the future.

Does your manufacturer use resin that is produced overseas? Internationally sourced materials may not have documentation of origin or comply with strict regulations. Plastic bottles and closures manufactured in other countries may have impurities in the resin or colorant that could leach or bleed into your products. Your plastic packaging partner should be able to provide documentation so you can rest assured your bottles are manufactured with the safety of your consumers in mind and that your product won’t be compromised.

Do you provide reliable service and supply chain?

Does your packaging manufacturer have suppliers that share a commitment to providing on-time delivery and properly spec’d materials that are the right choice for your product? Does it have flexible scheduling and strategically located facilities? You shouldn’t find yourself waiting for plastic bottles and closures to arrive when promised or dealing with missed deadlines that cause problems in your filling process.

Can you support my growing business?

Can your packaging partner grow as your business grows? It’s important that it be able to keep up with demand for your product and that its supply chain can match your manufacturing needs. As you add to your product line, is it capable of offering new and innovative packaging? A manufacturer that has a strong company growth model will benefit you now and in the future.

Are your products sustainable and eco-friendly?

Does your packaging supplier have a solid commitment to environmental sustainability? To many consumers, packaging made from recycled materials is important. There is strong market support for carbon-friendly alternatives in plastic production. Progressive plastic packaging manufacturers are actively working to provide alternatives to fossil fuel resins and instead, use resins produced from renewable resources (i.e. sugarcane). By partnering with a supplier concerned with reducing their carbon footprint and providing alternative and recycled raw materials, you can appeal to a growing segment of environmentally concious consumers, which can result in increased sales.

A real packaging partner for your products

Your business should develop a true partnership with the packaging supplier. The packaging company should be invested in your success and care about your business. Let’s face it, businesses depend on one another for continued growth. Look for a knowledgeable partner that wants to grow with you. The best plastic packaging suppliers realize that there is more to a relationship than just the financial transaction of buying packaging.

Remember, a brand consists of more than just a logo and company name. Quality packaging will reinforce your company standards and attract consumers to your product.

In short, seek a manufacturer that makes superior products that are unlikely to present downstream problems for your company, provides services and options that align with things you feel are important, and wants to build a long-term relationship so both of your businesses grow faster through the strategic partnership.