Automation has become the biggest competitive differentiator in cannabis, and it’s no longer optional. In fact, automation is essential for survival, scalability, and maintaining consistent quality while controlling costs.

Grand View Research estimated the value of the global cannabis technology market at $4.84 billion in 2023. By 2030, the market research firm expects that number to reach $23.46 billion — a 385-percent increase. There’s no question the industry is in the middle of an automation arms race. With each passing year, more manufacturers adopt automated systems such as pre-roll infusers, joint rollers, and even packaging systems. The reason is clear: Automation brings increased efficiency, stronger margins, and a chance to dominate in an increasingly competitive market.

But the real question isn’t who will rule the market. Instead, it’s what will happen to those who don’t automate.

Regardless of industry, automation in the United States is enabling the production of 44 percent more goods using 70 percent less labor than thirty years ago. The benefits of automation aren’t hypothetical, and they’re playing out in real-time across cannabis industry operations. Yet, a majority of manufacturing in the industry remains mired in the past. Manual processes and inconsistent workflows lead to high labor costs and slow production cycles.

Cannabis bottlenecks: a moving target

In manufacturing, bottlenecks are inevitable but often elusive. A bottleneck, in traditional manufacturing terms, is any point where materials accumulate and slow production. In cannabis, the location of bottlenecks is rarely static. As one part of the assembly line becomes more efficient, the constriction simply shifts downstream. Then, as systems are re-optimized, the pinch point may move upstream again. This dynamic makes efficiency a moving target across the production value chain, discouraging adoption of technologies that could streamline operations. So, while other industries have fully embraced automation, most cannabis manufacturers have remained in analog mode.

However, manufacturers that have implemented automation are not only seeing significant operational gains, but also discovering new opportunities to expand their businesses through entirely new product lines. For example, smart automation technologies are unlocking entirely new revenue streams. One manufacturer converted all its pre-rolls into infused joints using a robotic system built for precision infusion. The company didn’t change its volume or scale, but by introducing infusion, the brand realized a 10-percent increase in gross margin on what was essentially the same product. The perception of added value translated into real profit growth.

In another case, a concentrate manufacturer with no prior involvement in pre-rolls struggled to move large volumes of distillate. By adopting the same automated pre-roll system and offering infused pre-rolls as a white-label product, the company created an entirely new market channel. Six months after adding a single automated pre-roll infusion machine as a test, the company added a second to keep up with demand. Another six months later, they added a third. Today, the manufacturer is one of the top ten infused pre-roll producers in its market.

By aligning automation investments with market demand (such as the rising popularity of infused products), companies can scale more strategically and profitably. Macro forces like shrinking margins, price compression, labor shortages, material costs, increased competition, and maturing consumer expectations make every manual touchpoint in manufacturing a liability.

Smarter systems, stronger futures

If you’re considering automation for your operation, start by auditing your production line. Where are your bottlenecks? Once you’ve pinpointed the constrictions, implement automation to address one pain point at a time.

Your company doesn’t need more labor. It needs smarter systems. Automating can put you in the vanguard that will define the future of manufacturing.

Cannabis Automation Questions Answered

Why is automation important in cannabis manufacturing?

Automation reduces labor costs, improves consistency, and helps cannabis brands scale production while maintaining product quality.

How does automation solve cannabis production bottlenecks?

Automated systems streamline workflows, minimize manual touchpoints, and shift bottlenecks downstream, allowing brands to re-optimize more effectively.

What types of automation are used in cannabis manufacturing?

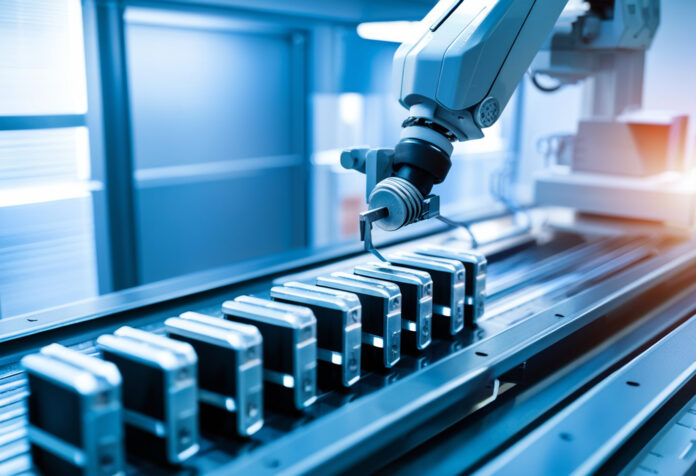

Common systems include pre-roll infusion machines, joint rollers, concentrate infusion, and automated packaging equipment.

What are the ROI expectations for cannabis automation?

Companies often see return on investment in months, with some achieving double-digit margin increases by automating processes like pre-roll infusion.

As a NASA Jet Propulsion Laboratory engineer, Nohtal Partansky helped develop and launch the MOXIE project, which is generating oxygen from the Martian atmosphere. Now a serial entrepreneur, he and Cassio Dos Santos Jr. co-founded Sorting Robotics, which creates cutting-edge automation technology for the cannabis industry.