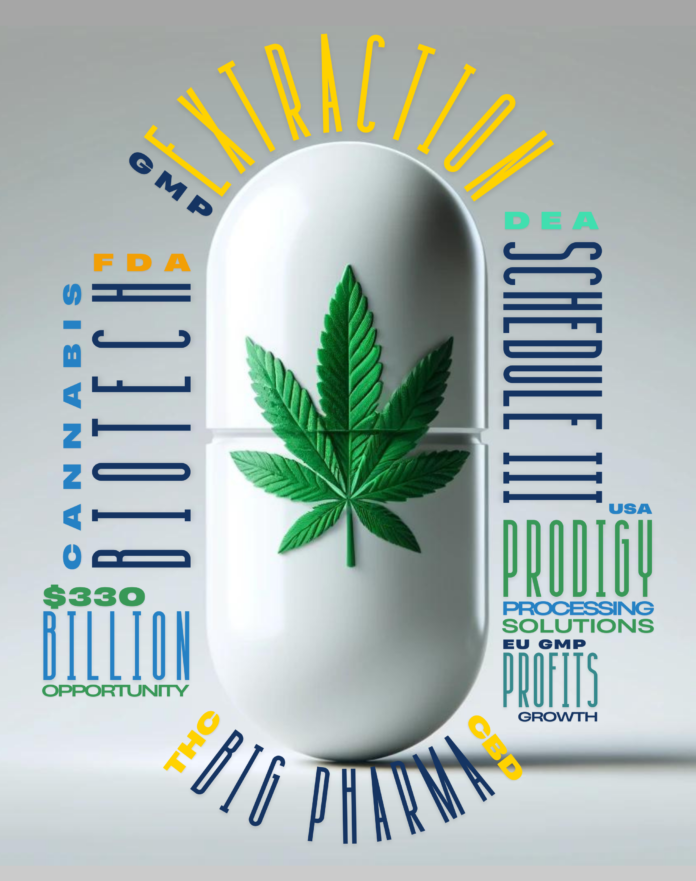

MIAMI — The impending DEA rescheduling of marijuana to a Schedule III controlled substance presents a momentous opportunity for state-licensed cannabis processing businesses to diversify revenue streams, exponentially increase profits, and expand their geographic reach worldwide.

Cannabis processing labs extract and purify oil from the cannabis plant to produce consumable goods containing THC, CBD, and a variety of other cannabinoids. Due to federal illegality, these operations have been limited to recreational or medicinal cannabis production and geographically confined to individual states or have operated as resource-intensive multi-state operators (MSOs).

Under Schedule III, cannabis-derived compounds will be federally legal as active ingredients in prescription medications. By pivoting towards pharmaceutical and biotech research and development, cannabis labs can unlock numerous lucrative possibilities for contract research and manufacturing with nationwide and international distribution.

The pharmaceutical sector boasts significantly higher profit margins compared to traditional cannabis markets, with gross profit margins averaging 76.5% and net income margins around 13.8%. Pharmaceutical companies offer a lucrative landscape for cannabis processors looking to diversify their revenue streams, distribution channels, and maximize profitability.

To capitalize on this groundbreaking opportunity, state-licensed cannabis labs will need to upgrade their operations to meet FDA GMP (Good Manufacturing Practices) standards, obtain DEA registration, and comply with additional regulatory guidelines, depending on the location of the extraction facility and the nature of the pharmaceutical processing and business goals.

Marc Beginin, CEO of Prodigy Processing Solutions, a leading force in cannabis extraction processing technology, emphasizes the transformative potential of this shift, stating, “By aligning with FDA regulations under Schedule III, cannabis processors can harness their expertise to drive innovation in pharmaceutical and biotech R&D, positioning themselves at the forefront of a growing industry.”

With FDA cGMP and EU GMP compliant extraction equipment and integrative services, Prodigy is at the forefront of guiding state-licensed labs to GMP compliance and facilitating their integration into the pharmaceutical and biotech industries. With a focus on innovation and quality, Prodigy empowers cannabis processors to embrace this paradigm shift and capitalize on the vast opportunities that lie ahead.

As the global pharmaceutical contract manufacturing market is projected to grow from $172 billion in 2023 to $330 billion by 2033, North American cannabis processors have a unique opportunity to capitalize on this trend.

“Our ASME and PSI certified extraction systems utilize only 316L pharmaceutical-grade stainless steel and are fully compliant with FDA cGMP and EU GMP standards,” continued Beginin. “Made in the USA, Prodigy’s systems are customizable to meet specific production needs while ensuring a smooth transition to pharmaceutical-grade production.”

In addition to its advanced extraction technology, Prodigy offers a comprehensive suite of ancillary equipment and services, including architecture, MEP design/build, product SOPs, certified extraction training, and GMP integration for food and pharmaceutical compliance worldwide.

With Prodigy Processing Solutions leading the charge towards pharmaceutical-grade standards, the future of cannabis processing is set for unprecedented growth and transformation under Schedule III.

For more information on how Prodigy Processing Solutions can help cannabis extraction businesses transition to pharmaceutical-grade production, visit ProdigyUSA.com.

About Prodigy Processing Solutions

Prodigy Processing Solutions is the leader of advanced extraction technology and integrative services for the cannabis and hemp industries. Committed to excellence, innovation, and compliance, Prodigy offers state-of-the-art extraction systems and comprehensive support services that meet or exceed FDA cGMP and EU GMP standards. Prodigy’s cutting-edge extraction systems, including 316L pharmaceutical-grade stainless steel systems certified by ASME and PSI, are designed to ensure seamless transitions to pharmaceutical-grade production.