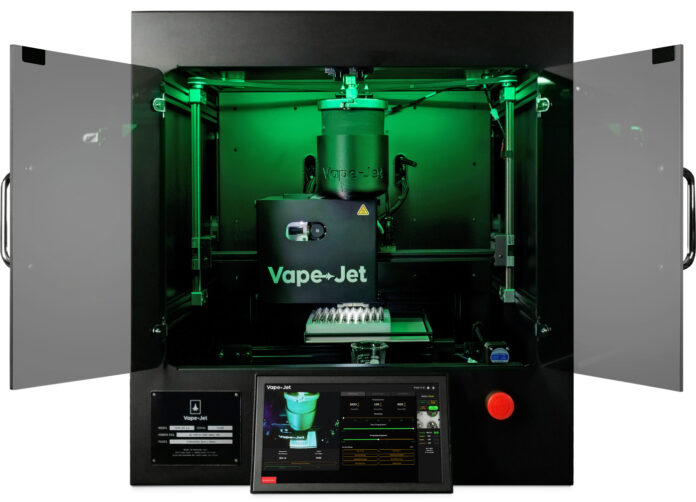

The latest evolution of Vape-Jet’s fully automatic platform eliminates inefficiencies and reduces labor costs while preserving terpenes and overall oil quality. Hand-built in Oregon using American-made parts, the Vape-Jet 4.0 Top Load, designed for larger batches and high-volume SKU production, can fill between 5,000 and 10,000 cartridges or AIO devices per shift.

The innovative top-loading feature streamlines processes and reduces downtime. Instead of removing and replacing a physical tank, operators pour oil directly into the top of the machine. Machines can be configured with a two-reservoir stack, doubling oil capacity to two liters.

“Loading extract from the top allows for more rapid changeover of batches,” said Chief Executive Officer Tim Marsh. “We stepped back and thought about how our machine not only does its job but also fits into the broader operational workflow. We realized batch changes were more of a constraint than tray runtime, slowing how many vapes could realistically be filled per day.

“Now, rather than loading and swapping reservoirs, the machine can essentially be filled directly with pre-heated extract,” he continued. “We eliminated complicated steps and unnecessary [standard operating procedures] to help our customers streamline their operations. This maximizes the uptime of the machine to drive lab throughput.

“There are also further benefits like a shorter fluid path for even more minimal product loss, less maintenance, and less to clean,” he said. “And most importantly, operators and managers have been loving the new experience.”

Three individual heat zones and a nitrogen-pressurized fluid path help protect product integrity by reducing degradation, evaporation, and oxidation. A pharmaceutical pump and software-based guided calibration procedures help operators consistently hit the desired fill volume.

Training, rapid-response support, and process consultation that includes data analysis and proactive guidance are part of the package.