The term “low and slow” has been passed around every growing circle. This drying method uses low temperature, moderate humidity, and long hang times—an ideal environment for breeding mold and bacteria. Controlling temperature and humidity during the drying process to maximize terpene and cannabinoid preservation is a delicate art form. While the post-harvest period can feel like a chore or expensive waiting game for some, many cultivators see it as an integral part of the plant life cycle.

From freeze drying in a matter of hours to much slower approaches, there are many contentious if not conflicting schools of thought when it comes to drying. However, cultivators should set their assumptions aside when considering alternative drying methods to achieve better and more profitable results.

Low temps and long times

Traditionally, many cultivators have used the low and slow drying method to process cannabis plants after harvest. Plants get chopped down, fan leaves get removed, and what’s left hangs until it’s dry. This classic method dries the cannabis plants at a temperature of 60 degrees with a relative humidity of 60 percent for 10 to 21 days. However, this lengthy 60/60 drying period can lead to issues with mold and bacteria growth within the buds.

“I actually prefer to keep temps lower, around 55 degrees if possible,” said Vancouver-based grower and breeder Harry Resin. “It helps to preserve the terps. For humidity, I may go as low as 60 right away but typically level out to around 69 percent.”

Benjamin Lind, co-founder and chief science officer for Humboldt Seed Company, also believes in a low and slow approach—very slow. He’ll often push the cure to six months to bring out the complex expression of the plant.

“We’re not creating mass-produced ground beef, you’re creating Wagyu,” Lind said, adding that outdoor cultivators should harvest early in the morning when the sun is low to avoid damaging valuable terpenes before moving plants to a cure room.

Pros:

- The low temperature helps slow the oxidation process.

- Cannabinoids and terpenes are preserved better with lower temperatures.

- It’s difficult to overdry, making the low and slow method more forgiving.

Cons:

- More time is required to dry in lower heat, providing more time for bacteria and mold to develop.

- The process takes valuable real estate in a dry room.

- Equipment and energy are needed to dehumidify and keep the space cool.

Freeze drying

Freeze drying, also known as cryodesiccation or lyophilization, has modern roots in the late-1800s. However, the tissue-preserving technology went largely unnoticed until World War II when blood plasma and penicillin were needed to treat wounded on the battlefield, spurring the development of a commercial freeze-drying process to make chemically stable and viable serums without refrigeration. In modern, cannabis-specific machines, no oxidation occurs between harvest and storage, ensuring cannabinoids and terpenes are preserved perfectly.

Horticulturist and author Ed Rosenthal recommends CryoCure, an advanced freeze-dry system for preserving cannabinoids and terpenes.

“The founders of CryoCure are cannabis aficionados,” Rosenthal said. “Unlike other freeze-dry machines, CryoCure equipment is dialed in for cannabis. The system is both time- and space-saving, and preserves the quality of the buds.”

The freeze-drying process is quick and provides top-shelf bag appeal but it’s not without its drawbacks. Buds may become brittle and fragile in this state, which requires attention to detail when handling and packaging to prevent damage to the delicate trichomes. Upfront costs for equipment can be steep, but there’s high potential for a long-term return on the investment thanks to freeze-drying machine efficiency and high-quality output.

Pros:

- Freeze drying can capture the exact state of the harvest.

- The process preserves cannabinoids and terpenes.

Cons:

- Buds become brittle, making long-term storage, packaging, and transport more challenging.

- The machinery requires a significant upfront investment with additional employee training to operate.

- The process is limited to small batches.

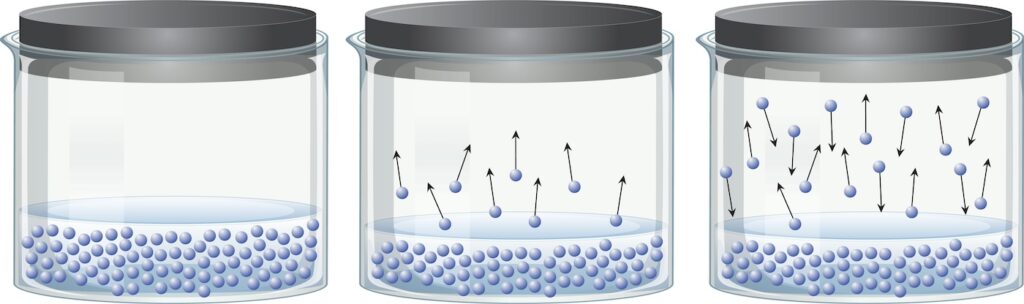

VPD and stepped drying

Skilled growers use temperature and humidity to control osmotic pressure for maximum water and nutrition uptake in the garden. During the drying stage, the same principles can be applied to move water from the plants to the atmosphere.

Stepped drying uses a temperature of around 70 degrees and a humidity of 50 percent for the first three to four days. After the initial phase, the temperature is decreased to 60 degrees and humidity is increased to 60 percent for seven to 10 days. By controlling temperature and humidity, a high vapor pressure deficit (VPD) can be established to quickly and efficiently dry the buds. After the initial moisture has been pulled from the flower, the VPD can be slowed to pull the final bits of moisture from the buds.

Pro:

- Effective moisture removal ensures buds are ready for the low and slow cure process.

- Plants can be bucked quicker and moved into cure bins faster, freeing valuable floor space and saving time.

Con:

- Extensive control systems are needed to maintain temperature and humidity.

- Higher temperatures can cause buds to oxidize and destroy terpenes.

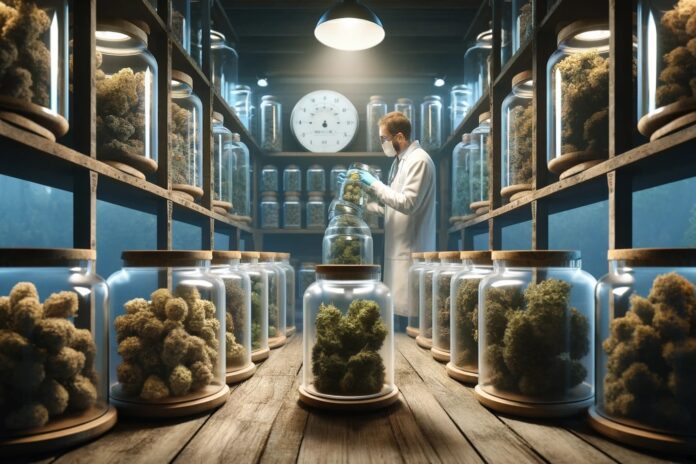

Long-term storage

Once the buds have reached their ideal moisture content, they are ready for packaging and storage. Keeping the bulk storage and consumer storage containers at the optimum humidity is critical for this process.

Grove Bags and Boveda use different materials like salts and specialized plastics to maintain humidity. Both can be used for bulk storage and consumer packaging. Grove Bags have become increasingly popular thanks to the brand’s patented TerpLoc technology, which helps keep cannabis fresh through the dry/cure process with options for long-term storage.

“TerpLoc is an unassuming technology being it’s in a flexible packaging form—in other words, a bag,” said Lance Lambert, chief marketing officer at Grove Bags. “But just like most technologies have affected our quality of life while saving time and/or money, TerpLoc holds a similar position in taking the work and guessing out of curing. You simply dry and trim as you would, then seal the flower in a TerpLoc bag for the suggested two weeks or more. That’s it. What you end up with is a perfectly cured end-product to enjoy.”

Other engineered products including CureTubes and Cure Pucks aim to eliminate the guesswork and provide real-time data with digital hygrometers or sensors to measure humidity and temperature inside the curing and storage container without breaching the seal. These products can be used for bulk storage, especially in preventing rapid oxidation.

Don’t waste resources

Reducing resource costs, whether time or energy, is critical for any cultivation facility. Having a clear vision and goal for the final bud allows cultivators to design a standard operating procedure for the optimal utilization of labor and energy. Ensuring long-term storage systems will help preserve the best flower for consumers and protect a grower’s bottom line.