The ability to optimize cultivation for cost, quality, and yield in a new market increases a brand’s opportunity to launch with attractive and sustainable profit margins needed for long-term success. Whether you’re preparing to build a new facility, applying for a cultivation license, or trying to make meaningful improvements to your existing cultivation business, there are a few options to help reduce recurring costs while improving the quality and wholesale value of your product at the same time.

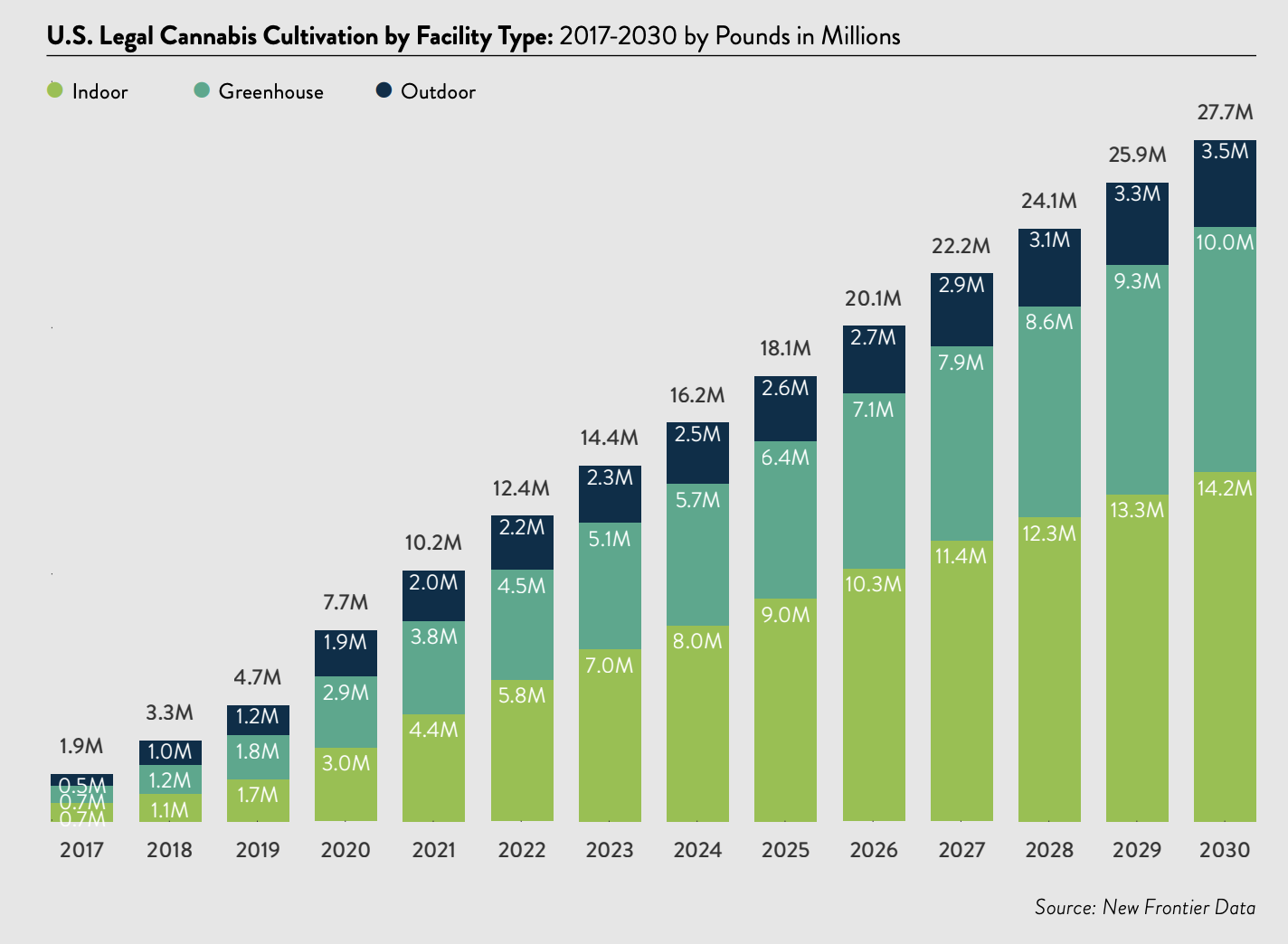

According to a recent report from New Frontier Data, legal cannabis production in the U.S. is poised to hit 27.7 million pounds by 2030 with an estimated value of $73 billion. As much as one-quarter of all legal cannabis produced in 2030 is expected to come from Florida, New York, New Jersey, and Virginia, highlighting the value of opportunities emerging in these relatively new markets. As the national market continues to expand eastward, we can expect to see an increase in indoor and greenhouse grows where market conditions favor if not demand controlled environments for efficient production at scale. With this in mind, consider the following six areas to optimize cultivation.

Automation is the future, find an expert

Like most agricultural and manufacturing industries, automation is becoming an increasingly integral part of efficient operations. As automated systems become more complex and reliant on high-tech hardware and software, you’re going to need a new type of cultivation expert and support staff to help run it. But that doesn’t necessarily mean hiring a new employee.

Automated irrigation and fertigation systems can detect the moisture content of the crops in a grow room and apply water as needed to maintain the optimal growing conditions, ensuring you’re using the least amount of water and nutrients possible. Canopy-level photo sensors can measure mixed lights and automatically adjust the spectrum, intensity, and physical distance to conserve energy consumption and ensure healthy growth. There are also centralized systems to ensure temperature, humidity, and carbon dioxide levels remain stable. And all of it can be managed off-site by a remote support team setup to provide 24/7 monitoring across any number of cultivation-related systems.

At one Maine-based facility, automated irrigation and environmental controls are contributing to better plant health, productivity, and quality. “Having irrigation and omitting hand watering has given our team a lot more time to spend on plant care which is a huge plus,” said Travis Carter, owner of Vice Cannabis. “I’ve also found that plants actually respond better to slower and lower volumes of water instead of watering by hand, all at once.”

But while automation has made it easier to support our crops, it’s of utmost importance that these systems are managed by technically qualified people alongside cannabis cultivation experts.

“While automation can lend to standardization and efficiency, growing quality cannabis is both science and art,” said Amanda Reiman, chief knowledge officer at New Frontier Data. “Knowledge about the plant, what it needs for optimal production, and even when to harvest is often passed down from generation to generation and held by experienced growers.”

The decision between greenhouse vs indoor is based on location

The overall operating costs of a new production facility can be significantly influenced by its location, beyond the most obvious expense of acquiring property or a lease in a high-priced zip code. When deciding between a greenhouse or indoor build, the biggest factors often overlooked are temperature and weather extremes outside, even with an indoor controlled cultivation facility.

Cooling and heating costs as well as humidity control can be higher for greenhouses and other mixed-light facilities in parts of the country that experience extreme heat or cold for multiple months of the year. Fully indoor spaces may be more economical in this case. However, without the proper design tolerances and high-quality insulated materials, even fully indoor grows in markets with extreme weather conditions will struggle to keep recurring energy costs down or suffer from inconsistent product throughout the year. States including the Dakotas, Maine, New Hampshire, and New York typically experience the country’s widest range in temperatures during summer and winter, making efficient operations more important in these states.

If your greenhouse or a mixed-light facility is located in a densely populated area, odor control is also an important factor to consider. This is especially important in neighborhoods with strong political opposition to cannabis legalization, because it could generate a larger number of complaints from locals. In the northeast where nearly one-fifth of the country’s population resides, the likelihood of odor complaints against facilities will inevitably increase.

Consider every product category

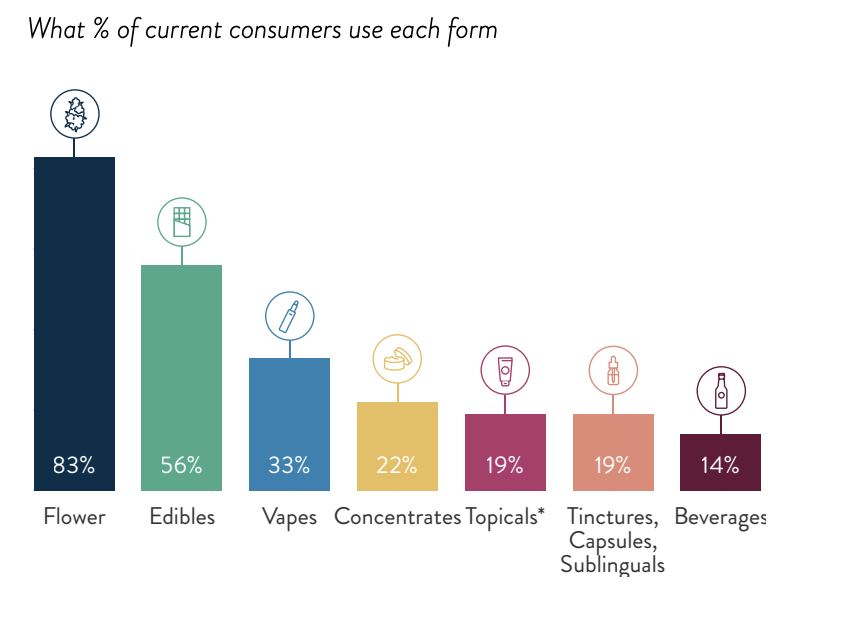

The broad category of value-added products which includes non-flower items like vapes, edibles, and topicals now account for half of all legal cannabis sales. Further, demand for non-flower products is growing more rapidly than for traditional flower, a trend that’s expected to continue as markets mature and customers seek higher potency and more discreet alternatives to fit cannabis into their lives in increasingly novel ways. With this in mind, many growers are choosing to cultivate outdoors when growing for extraction while reserving indoor cultivation with much higher production costs for smokable products where the look of the finished flower and trim are strong indicators of the final price.

“Consumers have different expectations for different form factors,” said Reiman. “What might be considered a quality vape cart is different than what people expect from quality flower. If flower is going into manufacturing, factors such as cure, trim job, and size of bud may not be as important.”

For brands interested in producing multiple product forms, planning to grow everything in the same location that benefits from economies of scale and efficient production practices may not actually be the most suitable path to long-term success. When launching in a new market, brands should seriously consider outdoor and indoor facilities.

Resource efficiency is becoming a critical factor

Mature markets like California and Colorado have been facing downward price pressure. In the Golden State, the number of cultivation licenses issued has outpaced the number of retail licenses, leading to oversaturation and lower wholesale prices. In Colorado, the average price per pound of flower has been cut by two-thirds in seven years, falling from $2,000 in 2015 to $700 in 2022.

Whether a business is trying to remain profitable or simply sustain itself through a difficult time in a developing industry, one way to mitigate these external factors is to focus on increasing resource efficiency—an area you can control.

“Indoor cannabis cultivation requires temperature control, humidity control, lighting, pest management, feeding, and other processes that can be more expensive if run on inefficient machinery,” said Reiman. “Sungrown farmers are able to utilize natural resources which make growing outside more cost-efficient.”

According to New Frontier’s report, energy is typically second only to labor in terms of production-cost line items, with many opportunities for cost-saving improvements.

“No matter the size of your grow room, it’s essential to construct a hermetically-sealed environment with the goal of reducing energy expenditures and CO2 consumption,” said Keith DeVore, President of PermaTherm Inc.

“A properly constructed grow room allows cultivators to keep their climate-controlled rooms at a neutral temperature. A hermetically-sealed space allows growers to pump CO2 into the room to the desired levels without experiencing any leakage resulting in loss afterward. The cost savings of having a hermetically sealed environment is unparalleled,” added DeVore.

Other areas like lighting have also taken major leaps in recent years, with innovations in energy-efficient light-emitting diode (LED) lights that are able to dramatically lower total electric use compared to older high-intensity discharge (HID) and metal halide (MH) lighting. LEDs also benefit from lower heat than older technologies, which leads to lower humidity and a reduction in heating, ventilation, and air conditioning (HVAC) as well as humidification system expenses.

The realities of climate change

Now more than ever, human beings are seeing the results of ongoing climate change. While cultivators in western states have been forced to deal with smoke contamination and drought, eastern states are facing greater risk of flooding—all factors that need to be considered when selecting a location for a new grow.

“Companies should choose methods that are as sustainable as possible while still complying with local and state laws. Second, companies need to be proactive. We know that water is going to become more scarce in some regions, that fires will continue to be an issue, and more severe weather can impact crops. Thinking ahead and designing facilities with these factors in mind can help prepare for what may come in the future,” said Reiman.

Live for today, plan for tomorrow

Although it might seem obvious, it’s important to point out that successful companies should plan in accordance with where the market is going as opposed to its current state. Cannabis is a relatively new industry and the market will look very different in 2030 than it has in 2022.

According to New Frontier Data, input costs will be a key determinant of future success and this can be seen as a major opportunity for companies that can adapt accordingly. Growers who are able to minimize their production costs, especially in areas of labor, energy, and water, while also differentiating themselves in the marketplace in terms of branding will be poised to have a significant edge.

“Growing outdoors will yield the lowest production costs. However, that is not possible in all markets or climates,” said Reiman. “Looking into sustainable sources of energy like wind, solar, etc. will bring production costs down by reducing reliance on other forms of energy.”

[…] love for the plant or basic economics, the best cultivators always look for worthwhile ways to optimize new and existing grows. We spoke with a handful of industry professionals who successfully mix cutting-edge techniques […]

[…] with its exacting requirements, has redefined the concept of specialized facilities. To ensure the success of their crops, growers rely on spaces where every environmental variable […]

[…] was big for us and shows how we like to enter states now. We finished a brand-new cultivation facility in December, and then we swooped in and got to the four-dispensary license cap right before adult […]

[…] the U.S. still could glean much from European practices and the continent’s long history of growing food and produce indoors. To start, consider the EU’s compliance with more widespread international health and safety […]

[…] is focused on emerging cultivation markets around the country and beyond, with roughly 40,000 square feet of equipment and exhibits. Dozens of […]