As more states legalize cannabis and consumer preferences in existing markets mature, cannabis concentrates’ market share will continue to expand. Trend data indicates concentrates, edibles, and vapes account for roughly 40 percent of total sales in the United States, with Generation Z and millennials contributing the most to spending in that sector among all the generations, pointing to a long-term upward trajectory for all concentrates-related categories.

Consumers are demonstrating their interest in a variety of cannabis extracts from topicals and tinctures to budder and wax. In the past, extract products were considered a high-end specialty item for experienced connoisseurs. However, extracts today are central to cannabis retail, especially in states like Pennsylvania that limit some categories such as pre-rolls or ban smoking flower altogether. To meet demand in different states, savvy manufacturers of all sizes are seeking high-quality and versatile equipment to produce a wide range of extracts and maintain a competitive edge.

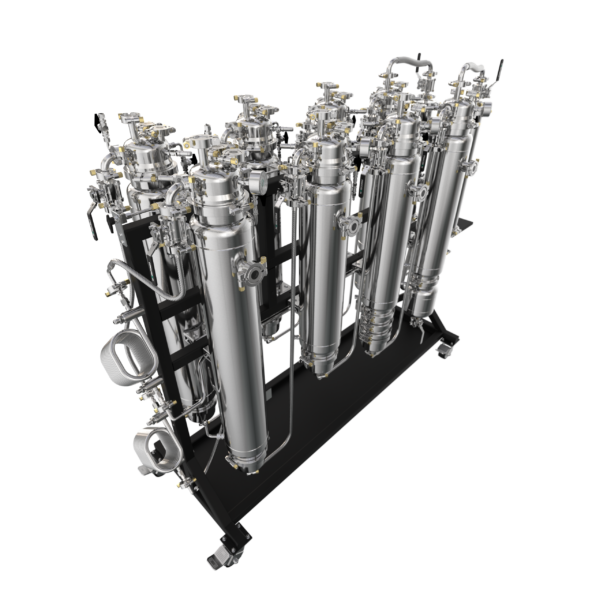

Precision Extraction Solutions by Agrify recognizes the diverse needs of cannabis manufacturers and designs its commercial equipment to accommodate those needs. The company’s newest piece of extraction technology, the PX10 hydrocarbon extractor, allows processors to produce a broad range of extracts using an efficient system that employs passive recovery to reduce batch times while increasing output. Processors may choose between butane, propane, and custom-blended solvent mixtures to fine-tune the production of concentrates including isolate, sauce, distillate, vape oil, shatter, wax, sugar, tinctures, and edibles ingredients.

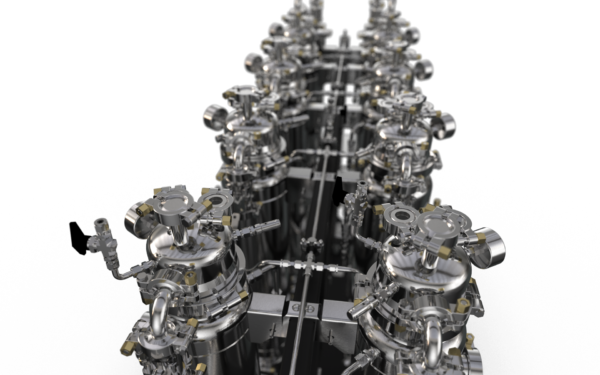

The PX line of closed-loop hydrocarbon extraction equipment offers a solution for businesses of all sizes. For mid-sized operations, the PX10 can process 10 to 20 pounds of flower per hour. Each of the three machines in the line is easy to operate in a linear process flow with conveniently located pass-throughs and ergonomically designed for operator comfort and safety during eight-hour shifts. Precision Extraction can help a small-scale cultivator who wants to expand into concentrates, a dispensary looking to add a house brand, or a vertically integrated multistate operator seeking higher levels of efficiency and output; there’s something in the PX line that’s well-suited for the task.

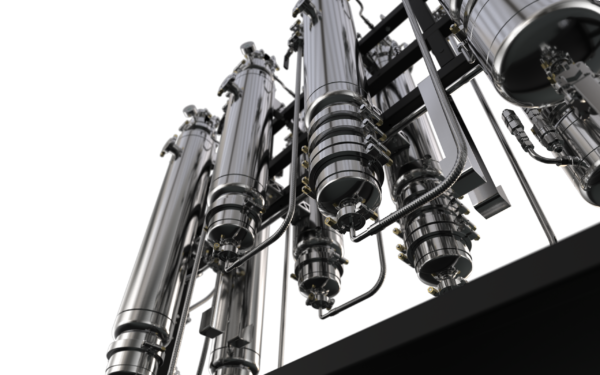

Precision Extraction’s new PX10 features twice the output and capacity of its predecessor, the PX5. Both the PX5 and the PX10 feature a passive recovery design that eliminates the need for a dedicated solvent recovery pump. With two five-pound material columns that can run parallel to each other, the PX10 can complete a 10-pound batch cycle in as little as 35 minutes and produce up to 160 pounds in an 8-hour shift. The machine also offers ultra-low-temperature operation and fast recovery times to help manufacturers keep up with demand during peak seasons. Its high-efficiency design has the potential to lower both capital expenditures and operating expenses while improving throughput.

Precision Extraction’s PX10 and PX5 are efficient and versatile. The machines can extract cannabinoids using butane, propane, or a blend of the two called isobutane. For customers seeking an ethanol solvent system, Precision also offers closed-loop ethanol extractors in the C-15 and C-40 Centrifuge that can process up to 40 pounds per run every 15 to 20 minutes. Depending on the type of extract the manufacturer wants to make and the specific strains being extracted, certain solvents may be more well-suited for the process. If a manufacturer has not already defined its ideal solvent blend, Precision can help identify a custom solution for the perfect concentrate consistency. If a customer wants their equipment to produce a variety of extract products, such as crumble, live resin, wax, and shatter, Precision’s technology can accommodate those needs as well.

Precision Extraction provides three-day, on-site installation training and several additional training options for specialties like craft concentrates. During the installation and training, customers are equipped with primary extraction training, post-processing basics, safe practices, and troubleshooting procedures. The craft concentrates training dives more deeply into terpene preservation, production techniques, material-specific operation parameter development, and the utilization of low temperatures, high pressure, and proper heat control for specific product types.

Precision Extraction machines are utilized across all of North America and beyond with equipment operating in Australia, Columbia, and South America. Their systems are ASME-certified and C1D1 compliant where applicable. Precision’s extractors are also peer-reviewed by engineers and PSI certified in all 50 states. The team behind Precision believes in the importance of operating safely, so they design and engineer butane extraction equipment to the highest safety standards.

The growing popularity and diversity of extract products coupled with the availability of high-quality extraction technology present a lucrative opportunity for those who are willing to invest in adaptable and dependable equipment. With solutions like the PX10, large-scale labs can run their extraction operations more efficiently, adjust parameters for new products, and maintain relevance in a rapidly developing industry. The machine’s modular design provides a cost-effective path to address any growth needs that arise and it is easily paired with other offerings from Agrify for rapid deployment of an entire post-harvest ecosystem.

As consumers continue to demand concentrates and infused products, cannabis companies with the ability to provide consistent, high-quality extracts will be well situated for long-term success. Those who invest in equipment from businesses that are committed to ongoing support will be able to grow more seamlessly as the market evolves. Machines like Precision’s new PX10 Hydrocarbon Extractor give manufacturers the adaptability, efficiency, and consistency required for success.